The smart manufacturing revolution is reshaping industries globally. Plate cutting machines play a pivotal role in this transformation. These machines enhance factory digitalization by improving efficiency and precision. As industries evolve, the plate cutting machine price and performance become critical factors.

I. Understanding Smart Manufacturing

1. Integration of Advanced Technologies

Smart manufacturing integrates advanced technologies into production processes. It focuses on automation, data exchange, and real-time monitoring. Plate cutting machines exemplify this shift. They seamlessly integrate with digital systems, enabling precise and automated cutting operations.

2. Flexibility and Adaptability in Manufacturing

Moreover, smart manufacturing emphasizes the need for flexibility and adaptability. Plate cutting machines are designed to meet these needs. They allow manufacturers to quickly adapt to changing production requirements.

II. The Role of Plate Cutting Machines

1. Automation and Labor Reduction

Plate cutting machines are essential in modern manufacturing. They automate cutting tasks, significantly reducing manual labor. This automation not only improves accuracy but also ensures consistent product quality.

2. Enhanced Production Speed and Cost Efficiency

Furthermore, plate cutting machines accelerate production processes. Faster operations lead to higher productivity and, consequently, lower costs.

3. Workplace Safety Improvement

In addition to these benefits, plate cutting machines enhance safety in the workplace. By automating dangerous tasks, they reduce the risk of human error and accidents. As a result, factories can maintain a safer working environment while improving output quality.

III. Impact on Factory Digitalization

1. Digital Networks and Real-Time Monitoring

Factory digitalization involves the adoption of digital technologies in manufacturing. Plate cutting machines are key enablers of this process. They connect to digital networks, allowing real-time monitoring and data analysis.

2. Data-Driven Decision Making

Additionally, plate cutting machines support data-driven decision-making. They collect and analyze data during operations. This data provides valuable insights into production efficiency and machine health. Consequently, manufacturers can make informed decisions that improve overall performance.

3. Customization and Flexibility in Production

Moreover, factory digitalization allows for greater customization and flexibility. Plate cutting machines enable manufacturers to produce complex designs with precision. This capability meets the growing demand for customized products in various industries.

IV. Economic Considerations: Plate Cutting Machine Price

1. Price Accessibility and Technological Advancement

The plate cutting machine price is a significant factor in digitalization efforts. As technology advances, prices may decrease, making these machines more accessible. Lower prices can accelerate adoption, particularly in small and medium-sized enterprises (SMEs).

2. Balancing Price and Quality

However, it is essential to balance plate cutting machine price and quality. Investing in reliable, high-quality machines ensures long-term benefits and reduces the need for frequent replacements.

3. Maintenance Costs and Long-Term Value

Furthermore, the cost of maintenance should be considered when evaluating the plate cutting machine price. High-quality machines often have lower maintenance costs, making them a more cost-effective option in the long run.

V. Transition to Digital Factories

1. Seamless Integration with Digital Tools

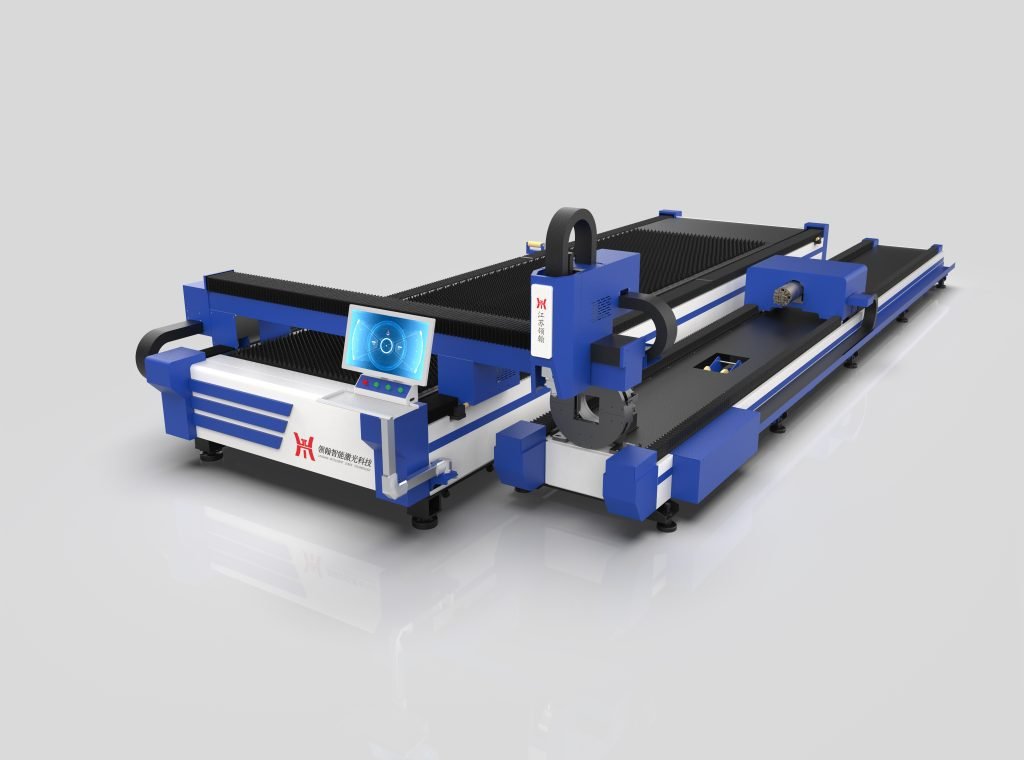

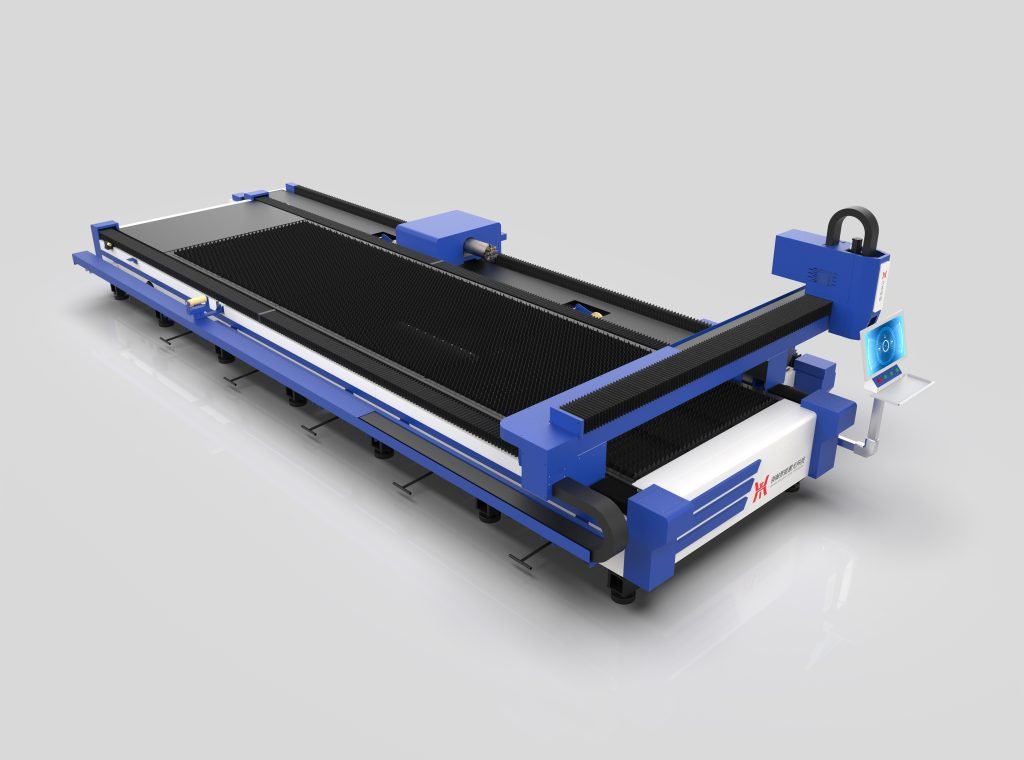

Digital factories represent the future of manufacturing. Plate cutting machines are at the forefront of this transition. They facilitate seamless integration with other digital tools. For instance, plate cutting machines can work with computer-aided design (CAD) software.

2. Interconnected Systems and Production Efficiency

Furthermore, digital factories rely on interconnected systems. Plate cutting machines play a vital role in these networks. They communicate with other machines and systems, creating a cohesive production environment. This connectivity enhances overall efficiency and reduces downtime.

3. Versatility and Precision in Manufacturing

Moreover, the ability of plate cutting machines to adapt to different materials and specifications makes them indispensable in a digital factory. They can handle a wide range of tasks, from cutting thin sheets to processing thick plates, all with the same level of precision.

VI. Challenges and Opportunities

1. Initial Investment and Long-Term Benefits

While plate cutting machines offer numerous benefits, challenges exist. One major challenge is the initial investment. High plate cutting machine price can deter some manufacturers. However, the long-term advantages often outweigh the costs.

2. Need for Skilled Operators and Training

Another challenge is the need for skilled operators. Digital machines require operators with technical expertise. Training programs are essential to ensure successful implementation. Manufacturers should invest in employee training to maximize the benefits of plate cutting machines.

3. Expanding Opportunities and Customization

On the other hand, the opportunities presented by plate cutting machines are vast. They open doors to new possibilities in manufacturing. Plate cutting machines enable manufacturers to produce complex designs with ease.

4. Contribution to Environmental Sustainability

Moreover, plate cutting machines contribute to environmental sustainability. By optimizing cutting patterns, they reduce material waste. This efficiency leads to less scrap and lower energy consumption, aligning with global sustainability goals.

VII. Sustainability and Environmental Impact

1. Waste Reduction and Energy Efficiency

Sustainability is a growing concern in manufacturing. Plate cutting machines contribute to sustainable practices. They reduce material waste by optimizing cutting patterns. This efficiency leads to less scrap and lower energy consumption.

2. Integration with Green Initiatives

Moreover, digital plate cutting machines support green initiatives. They can integrate with energy management systems, monitoring and reducing energy use.

3. Precise Control over Energy Usage

Furthermore, the digital nature of plate cutting machines allows for more precise control over energy usage. Manufacturers can track energy consumption in real-time and make adjustments as needed to ensure that operations remain as efficient as possible.

VIII. Future Outlook

1. Advancements in Plate Cutting Machines

The future of manufacturing is undoubtedly digital. Plate cutting machines will continue to evolve, offering even greater capabilities. As plate cutting machine prices become more competitive, adoption will increase.

2. Role of AI and Machine Learning

Moreover, advancements in artificial intelligence (AI) and machine learning (ML) will further enhance plate cutting machines. These technologies will enable predictive maintenance and real-time optimization.

3. Global Market Growth and Demand

Furthermore, as the global market continues to grow, the demand for plate cutting machines will rise. Manufacturers who invest in these machines today will be better positioned to meet the challenges of tomorrow.

IX. Conclusion

Plate cutting machines are revolutionizing manufacturing. They drive factory digitalization, improving efficiency and precision. While the plate cutting machine price is a consideration, the benefits are clear. Manufacturers who embrace these machines will gain a competitive edge in the digital age. As technology continues to advance, plate cutting machines will play an increasingly vital role in the smart manufacturing revolution.