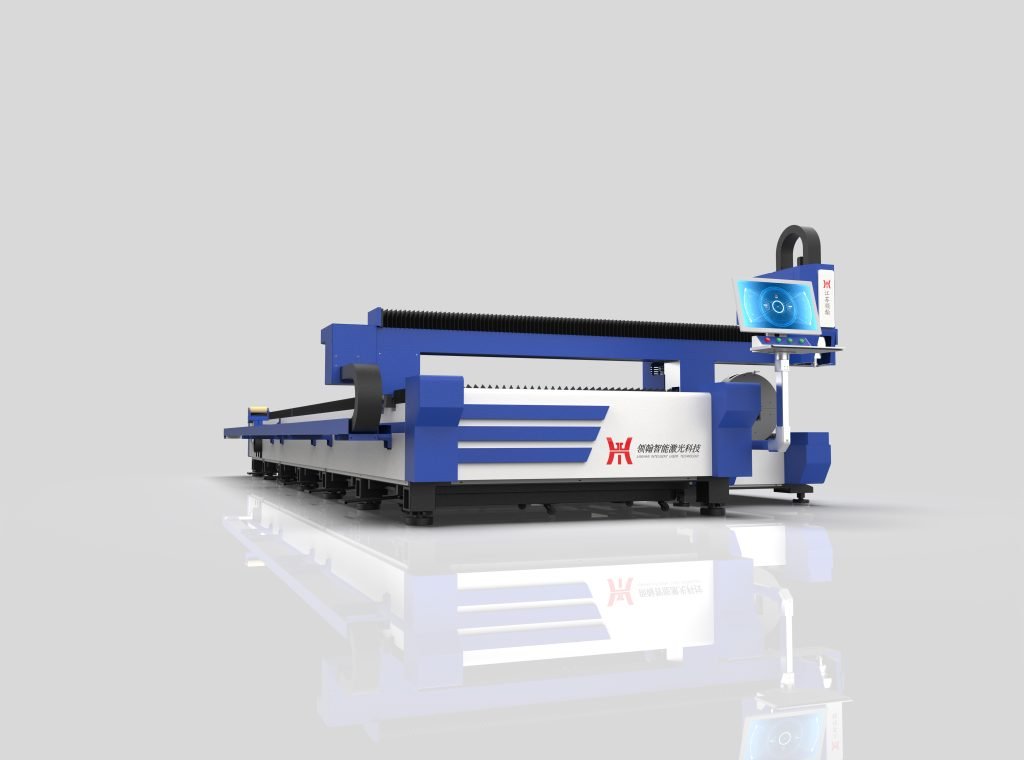

In today’s rapidly changing manufacturing world, flexibility is key. Small batch production has become more common, allowing companies to meet specific customer needs. One of the technologies driving this shift is the plate and tube laser cutting machine. This machine provides precise, quick, and customizable cutting for different materials. In this article, we’ll explore how the china plate laser cutting machine supplier is playing a crucial role in supporting small batch production. We’ll also examine how the laser plate cutting machine price affects accessibility for smaller manufacturers.

I. The Demand for Small Batch Production

The rise of custom products has increased demand for small batch production. Manufacturers need to be able to produce smaller quantities without sacrificing efficiency. Traditional cutting methods struggle with this demand, as they require more time and manual adjustments. However, laser cutting technology, especially when integrated with plate and tube systems, allows for quick changes between production batches.

A china plate laser cutting machine supplier can offer advanced machinery that easily adapts to different materials and designs. This flexibility is essential for small batch production, where different sizes, shapes, and materials are often required.

II. Flexibility with Materials

A plate and tube laser cutting machine can handle a variety of materials, from metal sheets to tubular structures. This versatility makes it ideal for small batch production. Whether you need to cut thin aluminum sheets or thick steel tubes, the machine adjusts easily. This ability to switch between materials without changing equipment speeds up the production process.

For companies looking to invest, the laser plate cutting machine price is a critical factor. However, the machine’s ability to handle diverse materials justifies the cost. With one machine, manufacturers can produce a range of products, reducing the need for multiple machines.

III. Speed and Efficiency

One of the biggest advantages of plate and tube laser cutting machines is their speed. Small batch production often requires quick turnaround times. The china plate laser cutting machine supplier provides machines that cut quickly and precisely. This speed helps manufacturers meet customer demands without compromising on quality.

In addition to speed, these machines offer high efficiency. With advanced automation features, the machine requires less manual input. Once programmed, the machine cuts multiple parts with minimal supervision. This efficiency reduces labor costs and increases output, which is especially beneficial in small batch production.

IV. Reduced Setup Times

Traditional cutting methods require extensive setup times, particularly when switching between materials. This can be a major issue in small batch production, where flexibility is key. The china plate laser cutting machine supplier offers machines that minimize setup times. Operators can quickly switch between jobs, adjusting the machine settings with ease.

This feature is crucial for companies that produce small batches of various products. Instead of wasting time on lengthy setup processes, manufacturers can focus on production. This allows them to produce more in less time, increasing overall productivity.

V. Precision and Quality

Precision is essential in small batch production, especially when customers expect high-quality, custom-made products. The laser plate cutting machine price may seem high, but the precision these machines offer justifies the investment. Laser cutting technology provides clean, smooth edges with no need for post-processing. This is particularly valuable for industries like automotive and aerospace, where high-quality finishes are essential.

In small batch production, consistency is important. The china plate laser cutting machine supplier ensures that each machine delivers consistent results, regardless of the batch size. This precision helps manufacturers meet customer expectations while minimizing waste.

VI. Customization Capabilities

One of the most significant advantages of using a plate and tube laser cutting machine in small batch production is customization. These machines can handle complex designs with ease. Whether cutting intricate patterns or simple shapes, the china plate laser cutting machine supplier provides machines that excel in customization.

For small batch orders, this customization capability is vital. Customers often request unique designs or specifications that require precise cutting. With a plate and tube laser cutting machine, manufacturers can easily adjust the machine’s settings to meet these needs. The ability to create custom products without additional tooling or equipment is a huge advantage in small batch production.

VII. Cost-Effectiveness

While the laser plate cutting machine price can be significant, the long-term benefits make it a worthwhile investment. For small batch production, the ability to reduce setup times, minimize waste, and increase efficiency directly impacts profitability. Manufacturers can take on smaller orders without incurring high overhead costs.

Additionally, the china plate laser cutting machine supplier often provides machines with low maintenance requirements. This reduces downtime and repair costs, further enhancing the machine’s cost-effectiveness. Over time, the savings generated from increased efficiency and reduced waste can offset the initial investment.

VIII. Automation and Workforce Needs

Automation plays a crucial role in the success of small batch production. The more automated the process, the less manual labor is required. A china plate laser cutting machine supplier typically offers machines with advanced automation features. These machines can operate with minimal human intervention, reducing labor costs.

For small manufacturers, this is a significant advantage. Automation allows them to take on more orders without needing to hire additional workers. It also reduces the risk of human error, ensuring consistent quality across all batches. The automation capabilities of the laser plate cutting machine make it an essential tool for small batch production.

IX. Scalability for Future Growth

Investing in a china plate laser cutting machine supplier can also support future growth. As demand for small batch production increases, the machine’s scalability allows manufacturers to expand their operations. They can take on larger or more complex projects without needing to invest in additional machinery.

The laser plate cutting machine price may seem like a large investment at first, but the scalability it offers makes it a smart long-term decision. Companies can start with small batch production and gradually scale up as their business grows. This flexibility ensures that the machine remains a valuable asset even as production demands change.

X. Environmental Benefits

Laser cutting technology also offers environmental benefits, which are important in today’s market. The precision of a plate and tube laser cutting machine minimizes waste. This is especially important in small batch production, where reducing waste can significantly lower costs.

Additionally, many machines from a china plate laser cutting machine supplier come with energy-efficient features. These machines consume less power than traditional cutting methods, making them more sustainable. For manufacturers looking to reduce their environmental impact, this is an important consideration.

XI. Заключение

The plate and tube laser cutting machine is revolutionizing small batch production. With its ability to handle multiple materials, reduce setup times, and offer precision, it’s an ideal solution for manufacturers. The china plate laser cutting machine supplier provides cutting-edge machines that deliver consistent quality and efficiency. While the laser plate cutting machine price may seem high, the long-term benefits far outweigh the initial investment.

Small batch production requires flexibility, speed, and precision. A plate and tube laser cutting machine provides all these qualities, helping manufacturers meet customer demands. As small batch production continues to grow, these machines will play a crucial role in shaping the future of manufacturing.