In today’s rapidly evolving manufacturing industry, the máquina de corte de placas por laser stands at the forefront of technological innovation and efficiency. As industries around the globe increasingly embrace the principles of Industrial 4.0, these machines become not just beneficial but essential. This transition from traditional manufacturing methods to modern, highly automated processes represents a significant leap forward. It reflects the seamless integration of digital and physical systems within production environments, leading to enhanced precision, reduced waste, and significantly improved productivity across various sectors. This shift is fundamentally reshaping the future of manufacturing.

I. The Rise of Industrial 4.0

Industrial 4.0 marks the fourth industrial revolution. It emphasizes automation, data exchange, and smart technology. The China laser plate cutting machine industry is at the heart of this revolution. These machines are becoming smarter, more efficient, and highly integrated into production lines.

Moreover, the concept of Industrial 4.0 focuses on the interconnection of devices. Factories use smart systems that communicate seamlessly. This connectivity improves efficiency, reduces waste, and enhances production quality. The laser plate cutting machine exemplifies this evolution. It now operates within a highly connected environment, ensuring precision and speed.

II. Traditional vs. Modern Manufacturing

In traditional manufacturing, manual labor dominated the production process. Operators controlled machines directly, relying on experience and skill. The China laser plate cutting machine has transformed this scenario. Modern machines now incorporate advanced automation and artificial intelligence.

In addition, traditional machines often faced limitations in precision and speed. They required frequent manual adjustments. Conversely, modern laser plate cutting machines integrate sensors and AI. These innovations ensure high accuracy and minimal downtime. As a result, production lines run smoothly, with fewer interruptions.

III. The Role of Laser Plate Cutting Machines

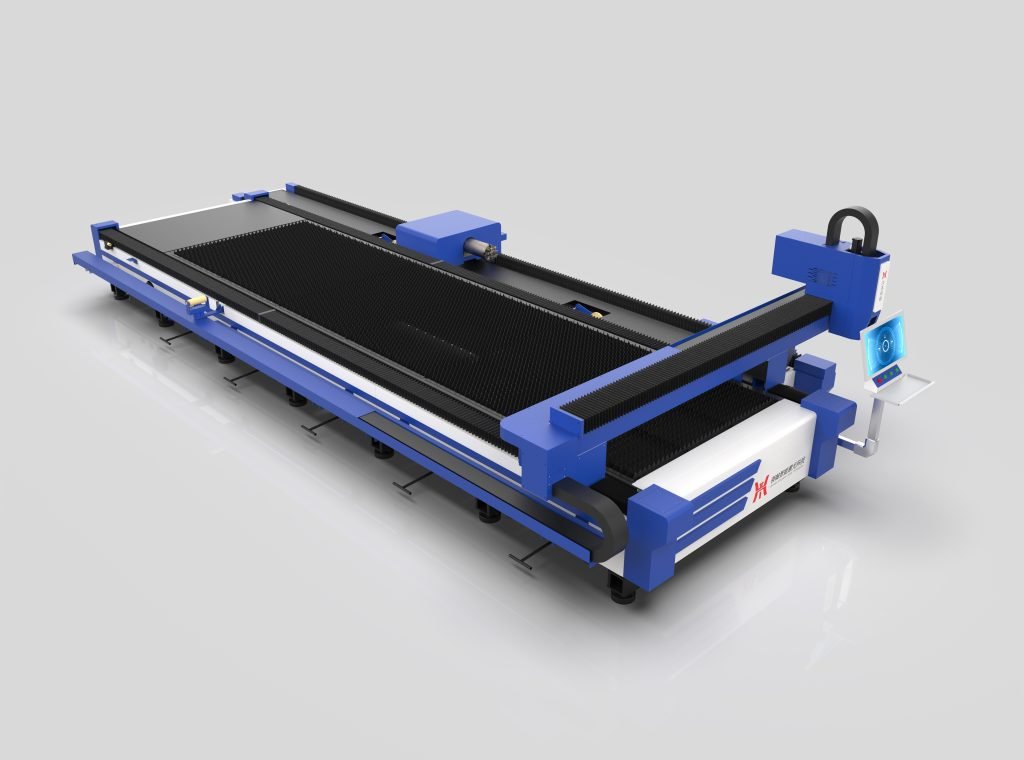

The laser plate cutting machine plays a crucial role in this transformation. It combines laser technology with automation. This combination offers unmatched precision, speed, and versatility. Moreover, these machines can handle various materials, including metals, plastics, and composites.

Furthermore, China laser plate cutting machines are leading the global market. They offer high-quality performance at competitive prices. Chinese manufacturers continue to innovate, introducing new features and improvements. This competitiveness has made them a preferred choice in many industries.

IV. Integration with Smart Technology

One of the key aspects of Industrial 4.0 is smart technology integration. Laser plate cutting machines are now part of this ecosystem. They connect with other devices, share data, and optimize operations. This integration enhances efficiency, reduces waste, and improves product quality.

For instance, modern China laser plate cutting machines can analyze data in real-time. They adjust cutting parameters based on material type and thickness. This adaptability ensures consistent results, even with varying materials. Additionally, these machines can communicate with other systems, ensuring seamless workflow integration.

V. Benefits of Transitioning to Modern Manufacturing

The shift from traditional to modern manufacturing offers numerous benefits. Firstly, it increases production speed. Laser plate cutting machines operate faster than traditional methods. They reduce the time required to complete tasks, boosting overall efficiency.

Secondly, the transition improves product quality. Modern China laser plate cutting machines offer higher precision. They produce cleaner cuts, with fewer defects. This precision translates into better final products, meeting higher quality standards.

Moreover, the integration of smart technology reduces operational costs. Laser plate cutting machines require less maintenance. They experience fewer breakdowns, reducing downtime. Additionally, these machines use energy more efficiently, lowering energy costs.

VI. Challenges and Solutions

Despite the benefits, transitioning to modern manufacturing poses challenges. One of the primary challenges is the initial investment cost. Laser plate cutting machines are expensive. However, the long-term savings in efficiency and maintenance offset this cost.

Another challenge is the need for skilled operators. Modern China laser plate cutting machines require technical expertise. Companies must invest in training programs to equip their workforce with the necessary skills.

Furthermore, integrating these machines into existing production lines can be complex. It requires careful planning and execution. However, the benefits of a seamless production line outweigh the challenges. Proper integration ensures smooth operations and maximizes the advantages of laser plate cutting machines.

VII. Future Prospects

The future of manufacturing lies in continued innovation. Laser plate cutting machines will play an even more significant role in this evolution. As technology advances, these machines will become more intelligent. They will offer greater precision, speed, and adaptability.

Moreover, China laser plate cutting machines will continue to lead the market. Chinese manufacturers are at the forefront of innovation. They are developing new features and improving machine performance. This leadership ensures that China laser plate cutting machines remain competitive globally.

Additionally, the integration of AI and machine learning will further enhance the capabilities of laser plate cutting machines. These technologies will enable machines to learn and adapt to different production scenarios. This adaptability will be crucial in meeting the evolving demands of the manufacturing industry.

VIII. Conclusão

In conclusion, the transition from traditional to modern manufacturing represents a significant shift. The laser plate cutting machine is at the core of this transformation. It exemplifies the integration of smart technology, automation, and precision in production processes.

Moreover, China laser plate cutting machines are leading this revolution. They offer high-quality, efficient, and cost-effective solutions. As the manufacturing industry continues to evolve, these machines will play an even more crucial role.

The future of manufacturing is bright, with laser plate cutting machines paving the way. They embody the principles of Industrial 4.0, ensuring that production processes are faster, more efficient, and more precise. The journey from tradition to modernity is ongoing, and the laser plate cutting machine is a vital part of this journey.