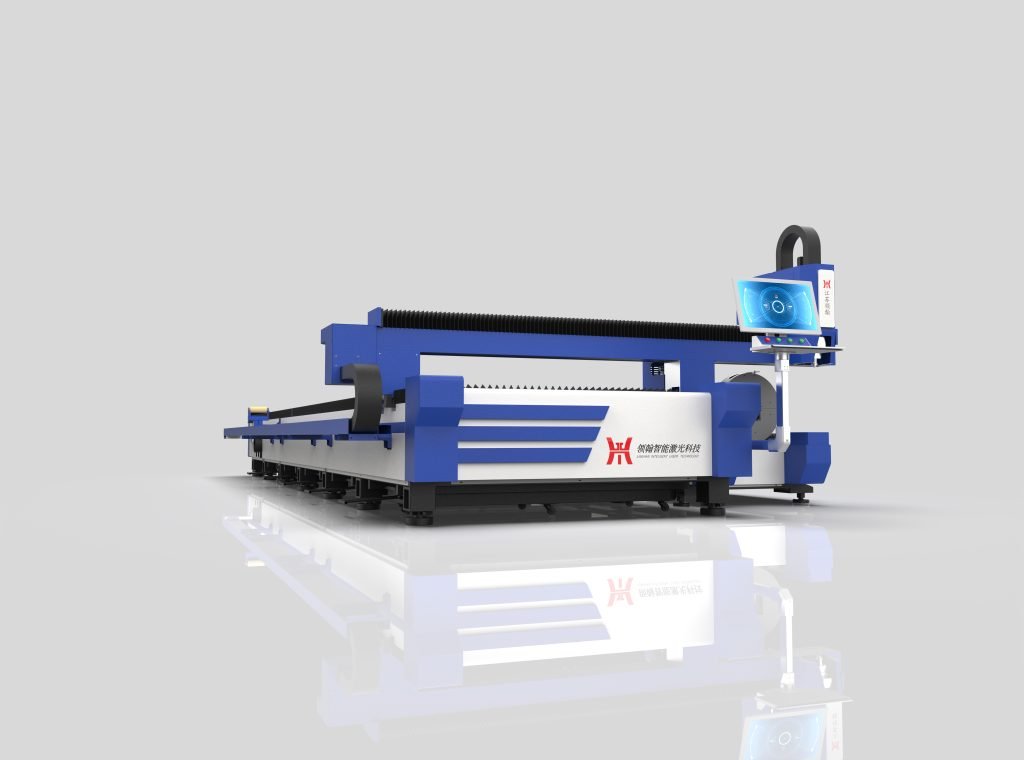

In recent years, laser cutting technology has made significant advances, transforming various industries, including agricultural machinery manufacturing. One of the most notable innovations in this field is the Plate and tube integrated laser cutting machine, a versatile solution designed to meet the demands of cutting both plates and tubes. As the agricultural machinery sector continues to evolve, these machines offer improved efficiency, precision, and flexibility in production. In this article, we will explore how the Plate and tube integrated laser cutting machine is revolutionizing agricultural machinery manufacturing and examine the factors influencing the plate cutting machine price.

I. The Need for Innovation in Agricultural Machinery Manufacturing

Agricultural machinery manufacturers face unique challenges when it comes to the production of complex equipment such as tractors, harvesters, and other farming tools. These machines require highly durable, precise components made from a variety of materials, including steel plates and tubes. Traditional cutting methods often struggle to meet the requirements for accuracy and speed, which has led to increased interest in laser cutting technology.

The introduction of the Plate and tube integrated laser cutting machine addresses these challenges by providing an efficient, all-in-one solution. Unlike conventional cutting tools, which often require separate machines for plate and tube processing, this integrated technology allows manufacturers to cut both materials seamlessly. This saves time, reduces labor costs, and ensures consistency in the production of agricultural machinery components.

II. Key Features of the Plate and Tube Integrated Laser Cutting Machine

1. Dual Functionality

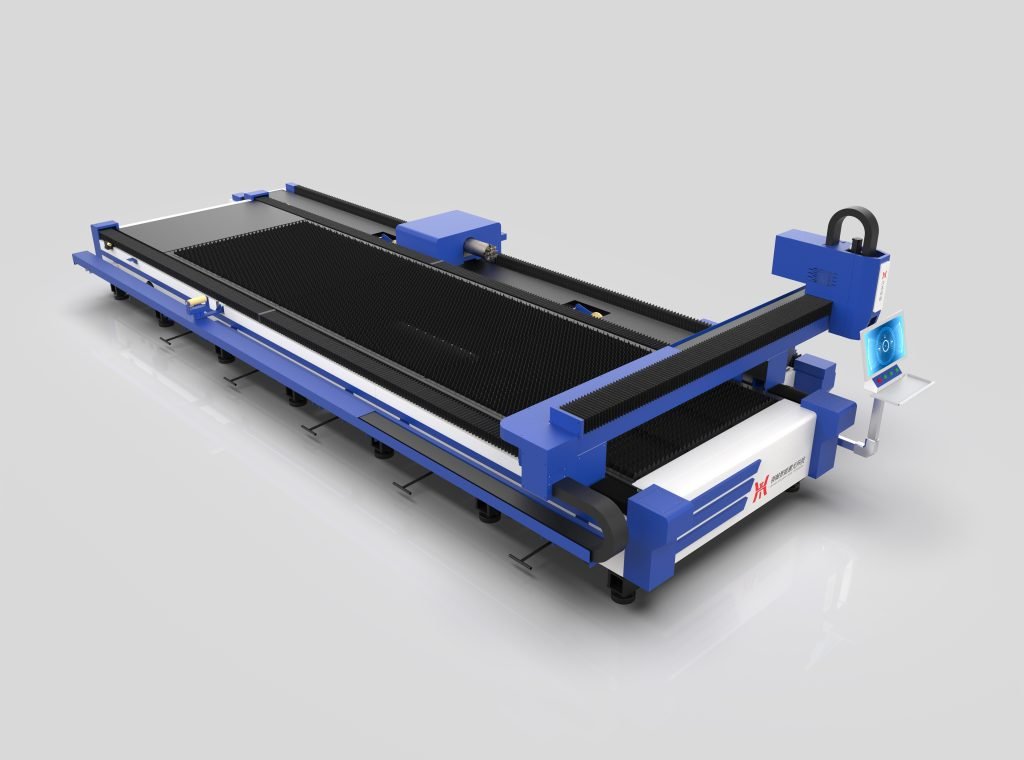

The most defining feature of the Plate and tube integrated laser cutting machine is its ability to handle both plate and tube cutting in a single operation. Whether the material is a flat steel sheet or a cylindrical tube, the machine’s versatile design allows for quick transitions between different materials without the need for additional equipment or manual adjustments. This dual functionality is particularly useful in the manufacturing of agricultural machinery, where both plates and tubes are commonly used in constructing structural frameworks and mechanical components.

2. High Precision and Accuracy

Agricultural machinery demands high levels of precision in its components to ensure proper functionality and longevity in the field. The Plate and tube integrated laser cutting machine uses advanced laser technology to deliver clean, precise cuts. It offers the ability to create intricate designs, complex shapes, and precise holes, which are often required in modern machinery. Moreover, the cutting process is highly accurate, with minimal material waste, further improving efficiency.

3. CNC Automation and Flexibility

Another significant advantage of the Plate and tube integrated laser cutting machine is its integration with CNC (Computer Numerical Control) systems. This automation allows for the programming of precise cutting paths, ensuring consistent results and reducing the risk of human error. Additionally, CNC systems provide the flexibility to quickly adjust cutting parameters, making it easy to switch between different components and designs. This is particularly beneficial for agricultural machinery manufacturers who need to produce customized parts based on specific project requirements.

III. Improved Productivity and Efficiency

The Plate and tube integrated laser cutting machine significantly boosts productivity by reducing the time and labor involved in material preparation and processing. Traditional methods often require multiple machines to perform the same tasks, leading to higher operational costs and longer production times. With the integrated macchina per il taglio laser, manufacturers can streamline their production processes, allowing for faster turnaround times without sacrificing quality.

Furthermore, the machine’s ability to cut different thicknesses and sizes of materials ensures that it can handle the diverse requirements of agricultural machinery manufacturing. From thin metal sheets to thick tubes, the machine’s versatility eliminates the need for multiple cutting tools, enhancing overall efficiency.

IV. Factors Influencing Plate Cutting Machine Price

When considering the purchase of a Plate and tube integrated laser cutting machine, understanding the plate cutting machine price is essential. Several factors contribute to the overall cost of these machines, including the laser power, machine configuration, and additional features.

1. Laser Power

One of the main factors affecting the plate cutting machine price is the laser power. Machines with higher laser power can cut thicker materials and operate at faster speeds, making them more suitable for industrial-scale production. For agricultural machinery manufacturers dealing with heavy-duty materials, investing in a machine with greater laser power may be a necessity. However, higher laser power typically comes at a premium cost.

2. Machine Size and Configuration

The size of the machine and its configuration also play a significant role in determining the plate cutting machine price. Larger machines that can handle bigger plates and tubes will generally be more expensive. Additionally, configurations such as automated loading and unloading systems, adjustable cutting heads, and multi-axis capabilities can add to the overall cost but provide enhanced functionality and convenience.

3. Brand and Warranty

The manufacturer’s brand and the warranty provided also affect the plate cutting machine price. Reputable brands with a proven track record in laser cutting technology tend to offer machines at higher prices, but these machines are often more reliable and come with better customer support and service options. Investing in a well-known brand can provide peace of mind in terms of machine performance and longevity.

4. Customization and Advanced Features

Many Plate and tube integrated laser cutting machines come with customizable features that allow manufacturers to tailor the machine to their specific production needs. Customization may include features like additional cutting tools, advanced software integration, or extended cutting capabilities for unique materials. While these options can increase the plate cutting machine price, they can also offer a higher return on investment by improving operational efficiency and product quality.

V. Practical Applications in Agricultural Machinery Manufacturing

1. Precision in Manufacturing Components

In agricultural machinery manufacturing, precision is crucial. The Plate and tube integrated laser cutting machine allows manufacturers to produce highly accurate components such as frames, axles, and engine mounts. These components require exact measurements to ensure proper assembly and functionality in the final product. The machine’s ability to cut both plates and tubes with minimal deviation ensures that every part fits perfectly during assembly.

2. Versatility in Meeting Diverse Requirements

The diverse nature of agricultural machinery means that manufacturers often need to produce a wide range of parts, from large structural elements to small, intricate components. The Plate and tube integrated laser cutting machine provides the flexibility needed to meet these demands, allowing manufacturers to quickly switch between different cutting tasks. This versatility not only improves efficiency but also reduces the need for multiple machines, lowering overall production costs.

3. Cost Efficiency and Material Savings

One of the significant benefits of using a Plate and tube integrated laser cutting machine is its ability to reduce material waste. Traditional cutting methods often result in excess scrap material due to inaccurate cuts or inefficient processing techniques. However, the precision of laser cutting minimizes material waste, leading to cost savings over time. In addition, the machine’s ability to cut complex shapes from a single piece of material reduces the need for additional assembly, further enhancing cost efficiency.

VI. Conclusione

The Plate and tube integrated laser cutting machine revolutionizes agricultural machinery manufacturing with its precision and efficiency in cutting plates and tubes. While the plate cutting machine price varies, investing in such equipment offers long-term savings through improved productivity and reduced waste. This technology is essential for meeting modern manufacturing demands and enhancing competitiveness.