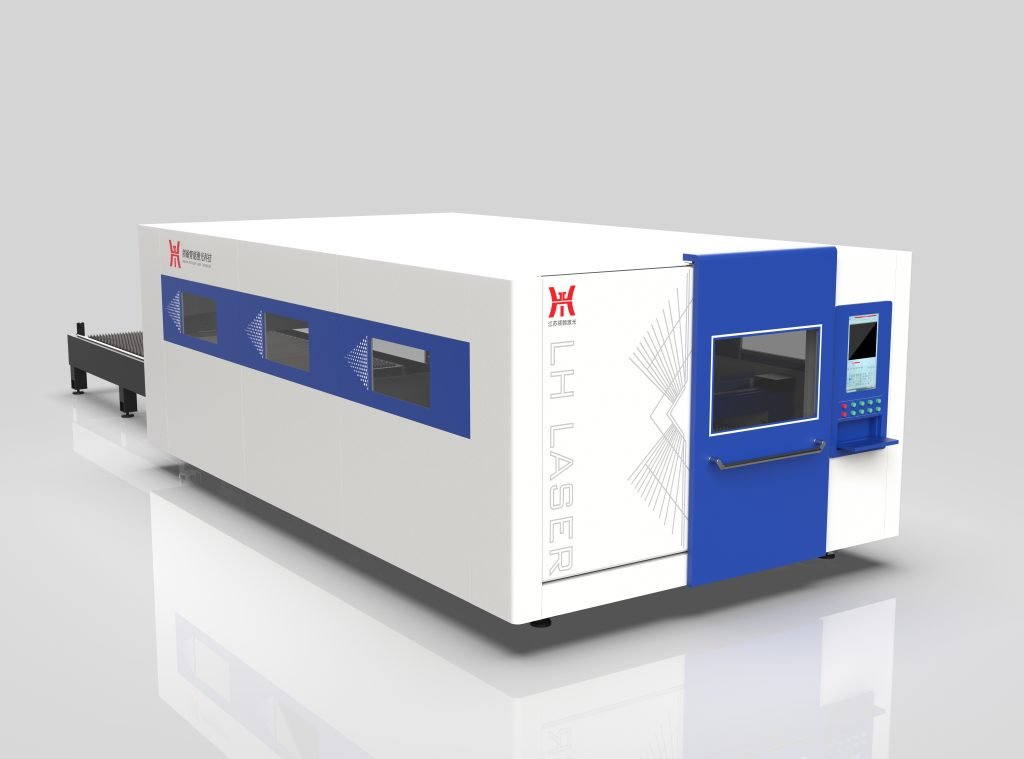

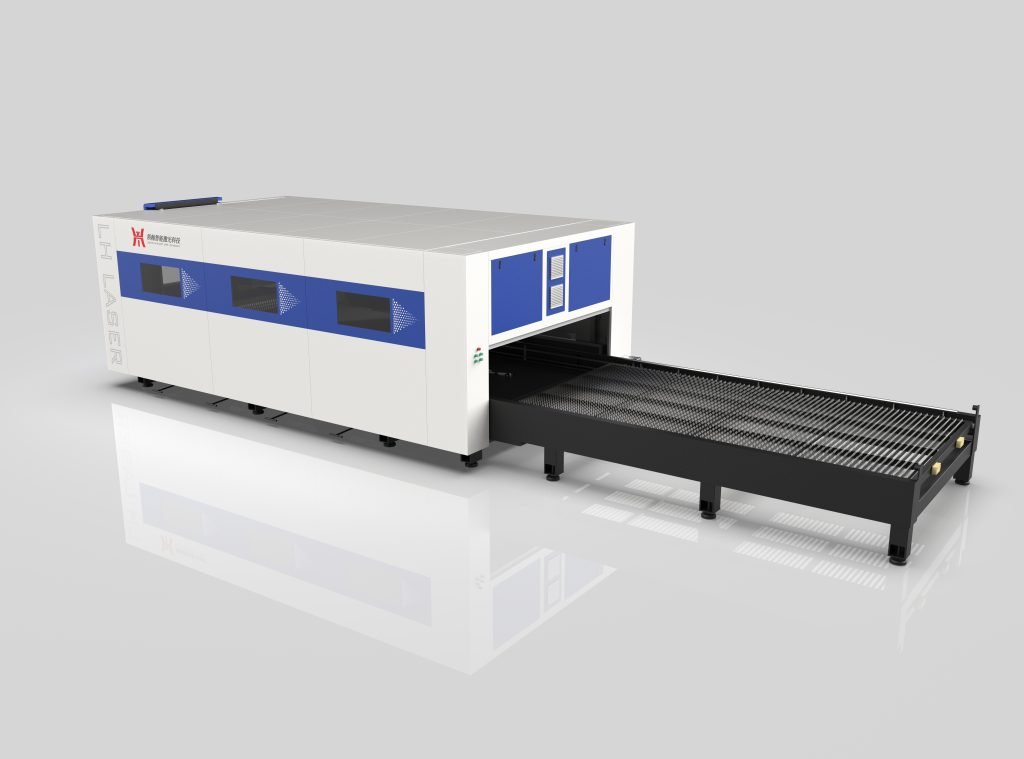

Manufacturing processes have evolved rapidly over recent decades. One groundbreaking advancement is the development of the máquina de corte por láser totalmente rodeada. This technology has transformed industries, especially those that rely on sheet metal laser cutting machines. It delivers unparalleled precision, safety, and efficiency. In this article, we explore the innovations behind this cutting-edge technology.

I. The Rise of Laser Cutting in Manufacturing

Laser cutting is not a new concept. However, recent innovations have made it more powerful. Manufacturers are increasingly turning to the fully surrounded laser cutting machine. These machines have significantly improved cutting accuracy and production times. Unlike traditional laser systems, they feature a fully enclosed design. This innovation boosts safety while maintaining high cutting standards.

II. The Importance of Precision

Precision is a critical aspect of manufacturing. A sheet metal laser cutting machine provides the precision manufacturers need. Whether cutting intricate designs or large-scale sheets, accuracy is key. Modern laser machines use advanced software and sensors to enhance precision. Fully surrounded machines offer additional protection during the cutting process. This reduces the risk of contamination or error.

III. Safety First with Fully Surrounded Machines

Safety is a growing concern in manufacturing environments. Traditional laser cutting systems often expose workers to various hazards. The fully surrounded laser cutting machine addresses these safety challenges. Its enclosed design ensures that no laser beams escape. This reduces the risk of burns or other injuries. Additionally, it provides better dust and fume containment.

IV. Increased Efficiency in Production

Efficiency is another driving factor in modern manufacturing. The fully surrounded laser cutting machine increases efficiency through its closed-loop design. This setup allows for continuous cutting without frequent interruptions. In comparison, open laser systems often require manual adjustments. Fully surrounded machines automate many of these processes, boosting productivity.

V. Enhancing Flexibility and Versatility

Versatility is essential for today’s manufacturing needs. Many industries, including automotive and aerospace, demand flexible production methods. A sheet metal laser cutting machine offers the flexibility to handle various materials and thicknesses. Fully surrounded systems add to this versatility. They can cut a wide range of materials, including metals, plastics, and even composites.

VI. Energy Efficiency and Sustainability

Manufacturers are increasingly focusing on sustainability. Traditional laser cutting systems can be energy-intensive. The fully surrounded laser cutting machine offers better energy efficiency. Its closed design minimizes energy loss during cutting operations. This contributes to a more sustainable production process. Moreover, these machines use fewer raw materials, reducing waste.

VII. Automation in Fully Surrounded Laser Cutting

Automation is a critical trend in the manufacturing industry. Fully surrounded laser cutting machines are at the forefront of this trend. These machines come equipped with advanced robotic systems. They can operate with minimal human intervention. This reduces labor costs and increases operational efficiency. Automation also allows for faster turnaround times.

VIII. Sheet Metal Laser Cutting Machine in Action

A sheet metal laser cutting machine can cut metals like steel, aluminum, and copper with ease. It is ideal for industries that rely heavily on metal parts. Fully surrounded machines add an extra layer of control and precision. This ensures that even the thinnest sheets of metal are cut with zero defects. Manufacturers can also create intricate shapes with high precision.

IX. Improved Material Utilization

Material waste is a common issue in manufacturing. However, the fully surrounded laser cutting machine minimizes this waste. The closed-loop design ensures that every inch of material is used efficiently. This improves material utilization, reducing overall costs. Additionally, this design prevents material distortion caused by external factors.

X. Real-World Applications and Benefits

Many industries have already adopted fully surrounded laser systems. Aerospace companies benefit from their ability to produce lightweight, precise components. Automotive manufacturers use these systems to create complex parts quickly. A sheet metal laser cutting machine is indispensable in these sectors. Its precision and speed help reduce production timelines significantly.

XI. Enhancing Competitiveness in Manufacturing

Manufacturers are under constant pressure to stay competitive. Adopting the fully surrounded laser cutting machine gives companies an edge. It allows for faster production, better quality, and lower costs. These machines also offer greater flexibility, which is essential in today’s market. Companies that embrace these innovations can meet higher production demands with ease.

XII. The Future of Laser Cutting in Manufacturing

The future of manufacturing is closely tied to technological advancements. The fully surrounded laser cutting machine represents the next step in this evolution. As these machines continue to improve, they will become even more integral to manufacturing processes. With the integration of AI and machine learning, laser systems will only get smarter.

XIII. Conclusión

The fully surrounded laser cutting machine is revolutionizing the manufacturing industry. It offers unmatched precision, safety, and efficiency. At the same time, it enhances productivity and sustainability. The sheet metal laser cutting machine is a vital tool for industries worldwide. Its innovations continue to push the boundaries of what’s possible in modern manufacturing. By adopting these technologies, manufacturers can stay ahead of the competition. They can also ensure high-quality production while reducing costs and waste.