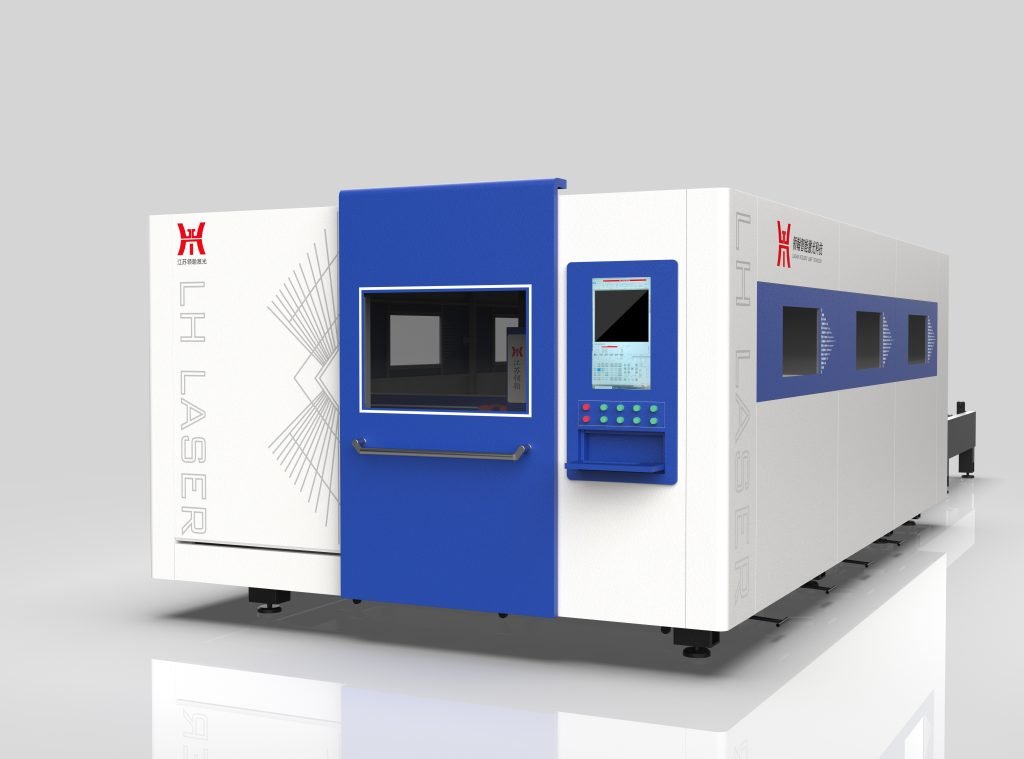

Laser cutting technology has revolutionized many industries. Precision and efficiency are crucial in manufacturing and design. The choice of the right laser cutter determines the quality of the final product. A fully surrounded laser cutting machine offers significant advantages, especially for precision tasks. This article explores why using a fully enclosed laser cutter is the best option for precision jobs, including working with metals using a cortadora laser metal.

I. Enhanced Precision and Accuracy

One of the primary reasons to choose a fully surrounded laser cutting machine is precision. The enclosed design ensures minimal external interference. Traditional open machines allow external factors, like dust or air, to impact cutting accuracy. In contrast, a fully enclosed system maintains a controlled environment, resulting in cleaner cuts.

Furthermore, these machines have advanced control systems. They provide consistent precision, making them ideal for complex designs. Whether you’re cutting intricate patterns or fine details, a fully surrounded laser cutting machine ensures that the results meet the highest standards. For metals, using a cortadora laser metal within an enclosed system guarantees exceptional precision.

II. Improved Operator Safety

Safety is always a top priority in any industrial setting. A fully surrounded laser cutting machine offers superior safety features. The enclosed design prevents exposure to laser radiation, which can be harmful. Unlike traditional machines, which may expose operators to the cutting process, fully enclosed systems completely shield the user.

Moreover, the enclosure reduces the risk of accidental contact with the laser beam. Operators can focus on controlling the machine without fear of injury. When cutting metal, using a cortadora laser metal with an enclosed system adds an extra layer of protection, making it safer to handle tough materials.

III. Contained Debris and Fume Management

Laser cutting produces debris, fumes, and dust. These by-products can affect both the machine’s performance and the work environment. A fully surrounded laser cutting machine efficiently manages these by-products. The enclosed design contains debris, ensuring a cleaner workspace.

Additionally, many enclosed machines feature advanced filtration systems. These systems remove harmful fumes before they escape the enclosure. This improves air quality, making the workplace safer and more comfortable. Particularly when using a cortadora laser metal, which generates metal dust, containing these particles is essential for a healthy work environment.

IV. Reduced Noise Pollution

Noise pollution is a common issue in manufacturing environments. Traditional open laser cutting machines generate significant noise during operation. However, a fully surrounded laser cutting machine reduces noise levels dramatically. The enclosed design absorbs much of the sound, creating a quieter workspace.

This reduction in noise not only benefits operators but also improves overall workplace productivity. Employees can focus better in a quieter environment, leading to fewer distractions and a more efficient workflow. For precision jobs, a calm and focused setting is crucial to achieving optimal results.

V. Protection of Sensitive Materials

Certain materials require special handling during the cutting process. A fully surrounded laser cutting machine provides an ideal environment for cutting delicate or sensitive materials. The enclosed system minimizes exposure to external elements, such as dust or moisture, that could affect material quality.

When cutting metals with a cortadora laser metal, this protection is especially important. Metals are sensitive to contaminants that could compromise the quality of the cut. An enclosed system ensures that the material remains clean, leading to better results and less waste.

VI. Increased Cutting Efficiency

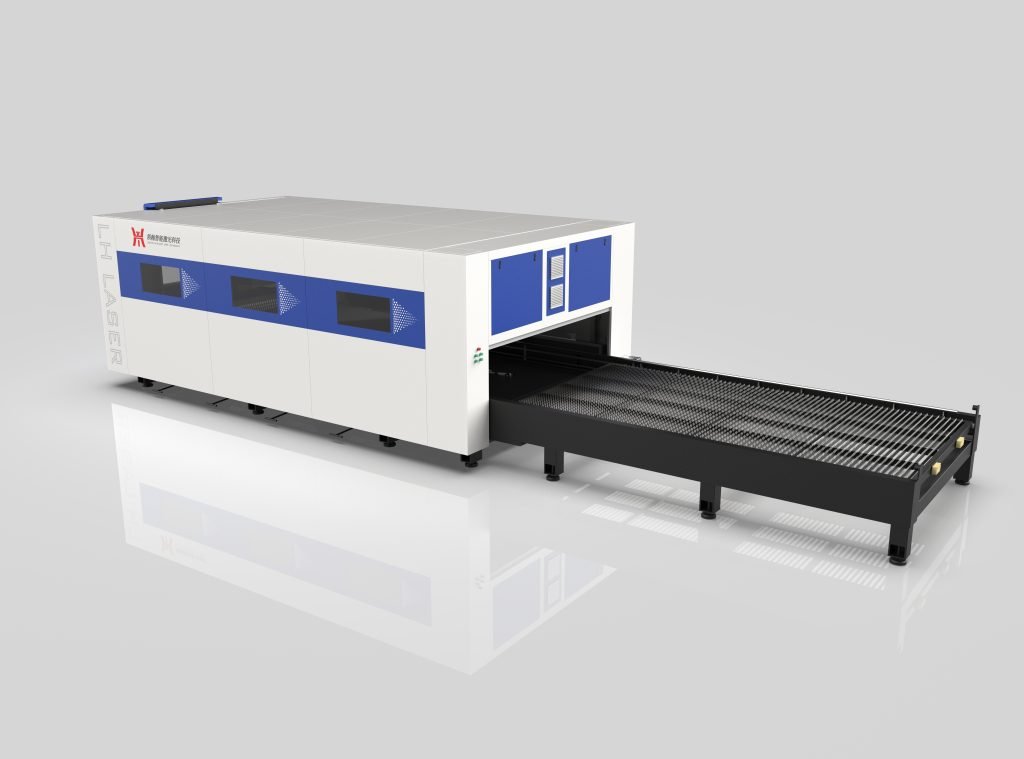

Efficiency is key in any production setting. A fully surrounded laser cutting machine improves efficiency by reducing downtime. The enclosed system allows for faster processing speeds. It also minimizes the need for frequent maintenance or cleaning, as debris is contained within the machine.

Moreover, fully enclosed machines often come with advanced automation features. These features streamline the cutting process, enabling operators to focus on other tasks. For metal cutting, using a cortadora laser metal in an enclosed system allows for faster and more accurate cuts, improving overall productivity.

VII. Enhanced Stability and Consistency

Stability is crucial for achieving consistent results. A fully surrounded laser cutting machine offers superior stability compared to open designs. The enclosure adds weight and rigidity, reducing vibrations during operation. This stability ensures that cuts remain consistent, even during long production runs.

For precision jobs, consistency is essential. Whether cutting metal or other materials, using a fully surrounded laser cutting machine guarantees that each cut is as accurate as the last. With a cortadora laser metal, the enclosed system ensures that even the toughest materials are cut with precision and uniformity.

VIII. Compatibility with Advanced Technologies

A fully surrounded laser cutting machine is often equipped with advanced technologies. These include CNC (Computer Numerical Control) systems, automated material handling, and laser power adjustments. These features make the machine more versatile and capable of handling a wider range of jobs.

When cutting metals with a cortadora laser metal, these technologies enhance precision and efficiency. Advanced control systems ensure that the machine can handle different metal types and thicknesses with ease. This versatility is crucial for industries that require precision cutting across various materials.

IX. Lower Operational Costs

While a fully surrounded laser cutting machine may have a higher initial cost, it offers long-term savings. The enclosed design reduces the need for frequent repairs or maintenance. It also improves energy efficiency by containing the laser’s energy within the cutting area. This leads to lower energy consumption and reduced operational costs over time.

For businesses that require metal cutting, investing in a cortadora laser metal with a fully enclosed design can result in significant cost savings. The machine’s durability and efficiency ensure a quicker return on investment, making it a smart choice for precision jobs.

X. Conclusion

In conclusion, a fully surrounded laser cutting machine is the ideal choice for precision jobs. Its enclosed design ensures safety, precision, and efficiency, while also protecting materials and the work environment. When working with metals, using a cortadora laser metal within an enclosed system guarantees superior results.

The combination of advanced technologies, enhanced safety features, and improved stability makes a fully enclosed machine essential for industries that rely on precise cutting. By choosing a fully surrounded laser cutting machine, manufacturers can achieve better results, reduce costs, and maintain a safer, more efficient workplace.