In the rapidly evolving manufacturing world, the role of plate cutting machines has become indispensable. However, as technology advances, integrating human-machine collaboration and augmented reality (AR) into plate cutting processes has emerged as a game-changer. This development not only enhances efficiency but also reduces errors and operational costs. In this article, we will explore how human-machine collaboration and AR are revolutionizing plate cutting machines, with a special focus on their impact on plate cutting machine prices.

I. The Evolution of Plate Cutting Machines

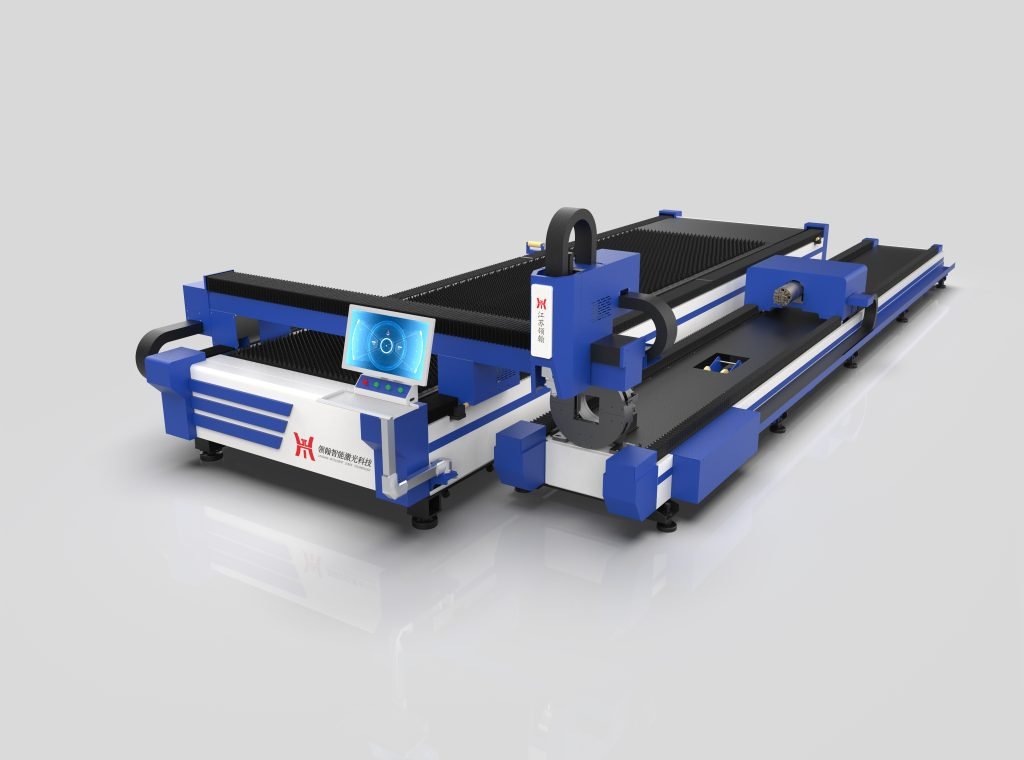

Plate cutting machines have come a long way. Initially, these machines were simple, manual tools. Over time, automation transformed them, making them faster and more precise. Today, advanced technologies like CNC (Computer Numerical Control) dominate the industry. However, even with these advancements, challenges remain. One significant challenge is optimizing human involvement in the cutting process.

II. The Need for Human-Machine Collaboration

Despite automation, human input remains crucial. Workers must often intervene to adjust machine settings, manage unexpected issues, and ensure quality. However, traditional methods of human-machine interaction can be inefficient. They require constant monitoring and can lead to errors. This is where human-machine collaboration shines. By enabling seamless interaction between workers and machines, it maximizes efficiency.

III. Enhancing Collaboration with Augmented Reality

Augmented reality (AR) offers a powerful solution to improve human-machine collaboration. AR overlays digital information onto the physical world, providing workers with real-time guidance. In plate cutting machines, AR can display cutting paths, machine diagnostics, and potential issues directly on the workpiece. This visual aid reduces the chance of errors and speeds up the process. Additionally, AR can provide step-by-step instructions for complex tasks, allowing even less experienced workers to perform at higher levels.

IV. Practical Applications of AR in Plate Cutting

The practical applications of AR in plate cutting are vast. For example, AR can assist in setting up the machine for different materials. It can display the optimal settings for each material, reducing setup time and ensuring accuracy. Additionally, AR can help in troubleshooting. When a problem arises, AR can highlight the affected areas and suggest corrective actions. This minimizes downtime and keeps the plate cutting machine operating smoothly.

Another critical application is training. AR can serve as an excellent training tool for new operators. By simulating various scenarios, it allows operators to gain experience without the risk of damaging materials or the machine. This leads to faster training times and higher confidence levels among workers.

V. The Impact on Plate Cutting Machine Price

Now, let’s consider the impact of these technologies on plate cutting machine prices. At first glance, integrating AR and human-machine collaboration might seem costly. However, the long-term benefits outweigh the initial investment. For instance, the increased efficiency and reduced errors lead to higher productivity. This means that fewer resources are wasted, and the machine operates more profitably.

Moreover, AR-driven training reduces the need for extensive training programs, which can be expensive. By shortening the learning curve, companies can save on training costs and get new employees up to speed faster. These savings can offset the initial cost of the technology, making it a worthwhile investment.

Additionally, as AR and human-machine collaboration technologies continue to gain traction and become more widespread, their development and production costs are expected to decrease over time. This reduction in cost will make these advanced features more accessible, even to smaller businesses that might have previously found them out of reach. As a result, the overall plate cutting machine price may eventually stabilize or even decrease, despite the addition of these sophisticated functionalities. This democratization of technology will allow a broader range of businesses to benefit from enhanced efficiency and precision, further driving industry innovation and competitiveness.

VI. Real-World Examples

Several companies are already successfully implementing these technologies. For example, a leading manufacturer integrated AR into its plate cutting machines. The results were impressive. They reported a significant reduction in setup time and a noticeable decrease in errors. Additionally, operators felt more confident and reported fewer incidents of machine downtime. These benefits directly impacted the company’s bottom line, making the investment in AR worthwhile.

Another example is a small fabrication shop that successfully integrated AR technology into their training programs. By leveraging AR, they significantly accelerated the proficiency of new operators compared to traditional methods, cutting the training period by nearly half. This rapid skill acquisition not only reduced training costs but also minimized production downtime. Consequently, the shop could handle a greater volume of work more efficiently and with fewer errors, ultimately boosting their overall revenue, enhancing their profitability, and allowing them to expand their client base in a highly competitive market.

VII. Future Prospects

Looking ahead, the combination of human-machine collaboration and AR in plate cutting machines is poised to grow. As technology advances, we can expect even more sophisticated applications. For example, machine learning algorithms could further enhance AR capabilities, providing predictive maintenance and real-time optimization. This would not only improve efficiency but also extend the lifespan of the machines.

Moreover, as AR hardware becomes more affordable, it will likely become a standard feature in plate cutting machines. This widespread adoption will drive competition among manufacturers, potentially lowering the overall plate cutting machine price. Companies that embrace these technologies early will have a competitive edge, benefiting from increased productivity and reduced operational costs.

VIII. Conclusion

In conclusion, human-machine collaboration and augmented reality are transforming the plate cutting industry. By enhancing the interaction between workers and machines, these technologies improve efficiency, reduce errors, and cut costs. While the initial investment may seem high, the long-term benefits justify the expense. As these technologies become more accessible, they will likely drive down the overall plate cutting machine price, making advanced features available to a broader range of businesses. Embracing these innovations now will prepare companies for the future, ensuring they remain competitive in an ever-evolving market.