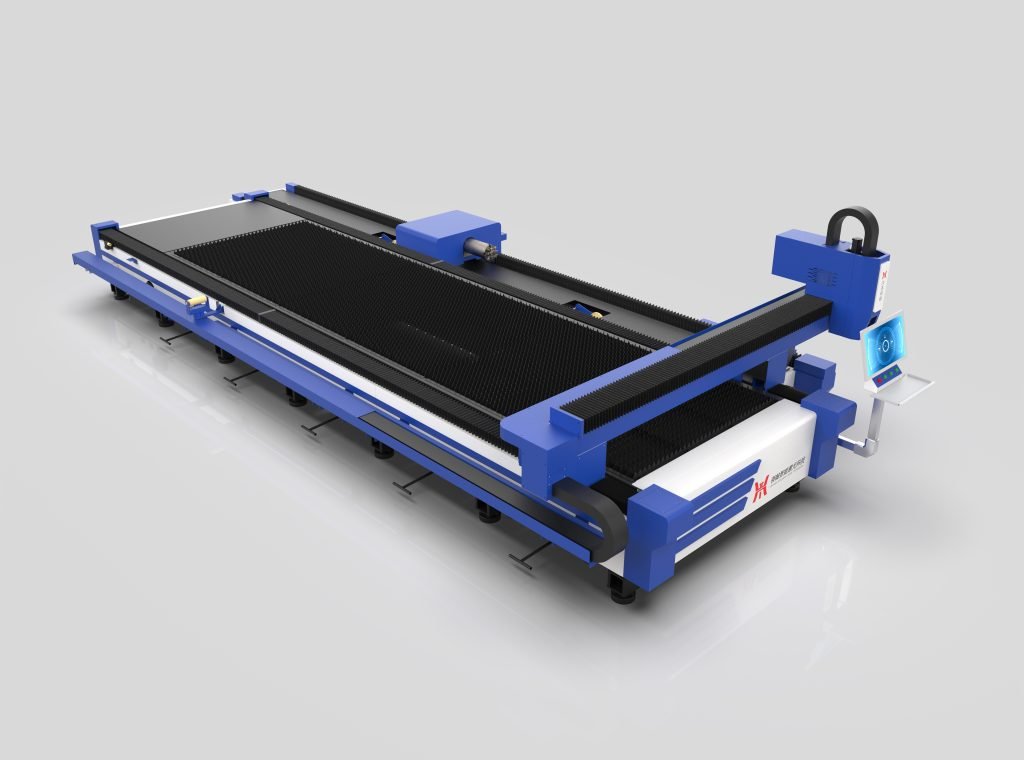

Choosing the right cutting head for your laser cutting machine is crucial. It affects both the precision and efficiency of your cuts. When working with a china plate tube laser cutting machine, the cutting head is particularly important. It needs to handle both flat plates and tubes with accuracy. This article will guide you through selecting the ideal cutting head for a laser tube cutting machine, ensuring optimal performance for all your cutting needs.

I. Understanding the Role of the Cutting Head

The cutting head is the part of the laser machine that focuses the laser beam. It determines how the laser interacts with the material. For a china plate tube laser cutting machine, the cutting head must be versatile. It needs to cut through different materials and shapes. It must also maintain high precision for both flat plates and round tubes.

II. Importance of Flexibility

When selecting a cutting head, flexibility is key. A laser tube cutting machine often deals with various material types and thicknesses. The cutting head must be adjustable to handle these variations. Whether you’re cutting thin tubes or thick plates, the cutting head should adapt quickly. This ensures that each cut is smooth and accurate.

III. The Role of Autofocus Technology

Autofocus is a critical feature for any cutting head. With autofocus, the cutting head automatically adjusts the focal point. This is especially useful in a china plate tube laser cutting machine, where the material thickness can vary. Autofocus ensures that the laser stays focused on the material surface. This feature speeds up the cutting process and improves accuracy.

IV. Choosing Between Fixed and Adjustable Heads

You can choose between fixed and adjustable cutting heads. Fixed heads are less flexible but work well for consistent materials. However, if you plan to cut multiple materials, an adjustable head is better. A laser tube cutting machine benefits from an adjustable head because it allows for more precision. You can fine-tune the laser to fit the material, ensuring a clean cut every time.

V. Material Considerations

Different materials require different cutting approaches. For a china plate tube laser cutting machine, the cutting head must be able to handle metals, plastics, and composites. When cutting metals like steel or aluminum, the cutting head needs to withstand high temperatures. For softer materials like plastics, it must prevent burning or melting. Always consider the materials you’ll be working with before choosing a cutting head.

VI. Cooling Mechanisms

The cutting head must remain cool during operation. Laser cutting generates a lot of heat, especially when cutting thick materials. Many cutting heads come with built-in cooling systems. These systems prevent the cutting head from overheating. A laser tube cutting machine that works for long periods benefits from water-cooled heads. They keep the cutting head at an optimal temperature, ensuring consistent performance.

VII. The Importance of Nozzle Design

Nozzles are a crucial part of the cutting head. They direct the laser beam and assist in the cutting process. For a china plate tube laser cutting machine, the nozzle design can affect the quality of the cut. A well-designed nozzle provides smoother airflow and better precision. It also prevents material buildup on the cutting head, extending its life.

When selecting a nozzle, look for one that matches your cutting needs. For example, a smaller nozzle is better for thin materials. A larger nozzle works well with thicker plates. The right nozzle ensures the laser tube cutting machine performs at its best.

VIII. Maintenance and Durability

Durability is an important factor when choosing a cutting head. A china plate tube laser cutting machine often runs for long hours in industrial settings. The cutting head must be able to withstand frequent use. Look for cutting heads made from high-quality materials. They last longer and require less maintenance.

Regular maintenance is also essential for keeping your cutting head in top condition. Clean the nozzle and lens regularly to avoid buildup. Replace any worn-out parts to maintain the efficiency of your laser tube cutting machine.

IX. Cutting Speed and Efficiency

The cutting head plays a significant role in the machine’s speed. A fast, efficient cutting head allows the china plate tube laser cutting machine to complete jobs quicker. This is especially important for large-scale manufacturing. When selecting a cutting head, check the manufacturer’s specifications for speed. Ensure the head can handle the speeds you need without sacrificing quality.

X. Lens Quality and Focus Control

The lens in the cutting head focuses the laser beam. High-quality lenses are essential for clean, precise cuts. When choosing a cutting head for your laser tube cutting machine, ensure it comes with durable, high-quality lenses. Focus control is another critical feature. The lens must maintain a sharp focus on the material throughout the cutting process.

Poor focus can result in uneven cuts or material damage. A cutting head with automatic focus control adjusts itself as needed. This ensures that the china plate tube laser cutting machine maintains its precision, even on complex cuts.

XI. Gas Flow Control

Gas flow is an important part of the laser cutting process. The gas helps to blow away molten material during cutting, resulting in a cleaner edge. For a china plate tube laser cutting machine, controlling the gas flow is essential. The cutting head should offer precise gas control to ensure that the laser works effectively. This reduces the risk of imperfections on the cut surface.

Different materials require different gases. For example, nitrogen works well with metals, while oxygen might be better for cutting thicker plates. Your cutting head must support these gas variations to handle multiple materials.

XII. Cost and Value

Finally, consider the cost of the cutting head. Cutting heads vary widely in price based on their features. However, it’s essential to balance cost with value. A laser tube cutting machine needs a durable, high-performance cutting head. Investing in a high-quality head may cost more upfront, but it will pay off in longevity and precision.

Cheap cutting heads often wear out quickly, leading to frequent replacements. Over time, this can be more expensive than investing in a top-quality head from the start.

XIII. Conclusion

Choosing the right cutting head for a china plate tube laser cutting machine is essential for achieving the best results. Whether you’re cutting flat plates or tubes, the cutting head must be flexible, durable, and precise. Look for features like autofocus, cooling mechanisms, and gas control to enhance performance. Consider the materials you’ll be cutting and choose a head that matches your specific needs.

With the right cutting head, your laser tube cutting machine will perform at its peak, delivering accurate, clean cuts across multiple materials. This ensures that your investment in laser cutting technology pays off, offering high-quality results every time.