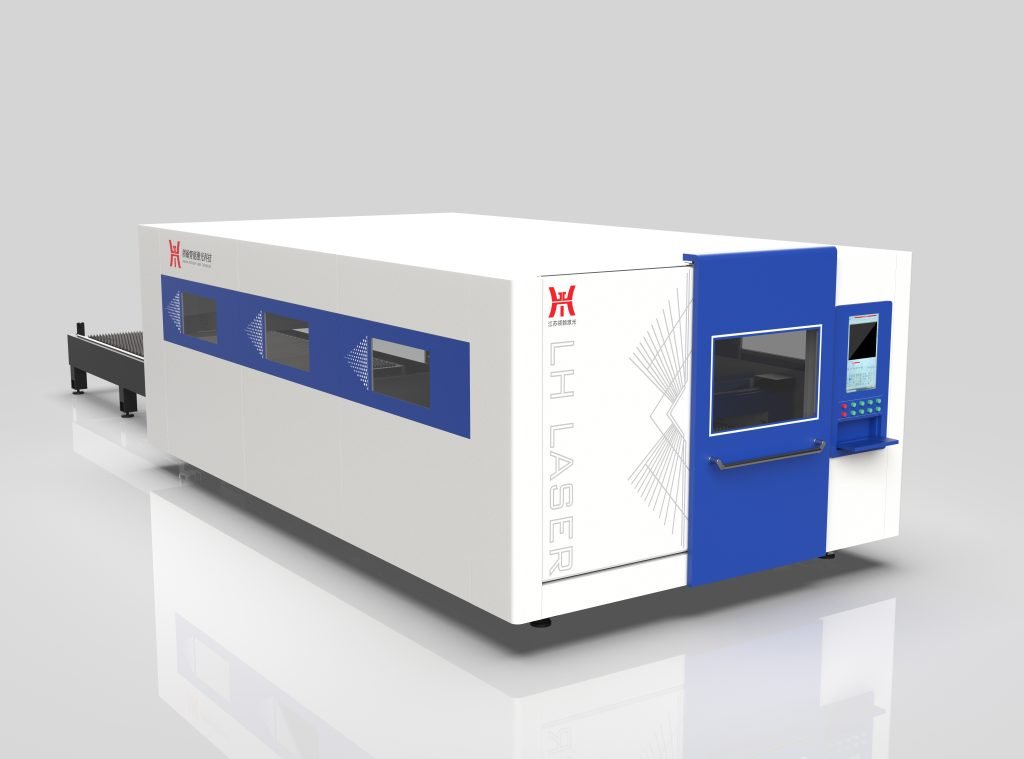

Laser cutting technology has transformed manufacturing. It allows precision and speed in cutting materials. However, safety remains a major concern. Traditional laser cutting machines have open designs, which expose operators to risks. In response, manufacturers developed the fully surrounded laser cutting machine. These enclosed systems provide enhanced safety for operators and the environment. In this article, we will explore how the fully surrounded laser cutting machine improves safety in various ways.

I. Protection from Laser Radiation

Laser radiation can be hazardous. Exposure to laser beams can cause severe injuries. The fully surrounded laser cutting machine eliminates this risk. Its enclosed design contains the laser beam within a sealed chamber. As a result, operators are fully protected from direct laser exposure. Traditional laser cutting machines may require operators to wear protective gear. With a fully enclosed machine, this is no longer necessary.

Moreover, the machine’s enclosure is made of materials that absorb stray laser radiation. This prevents harmful reflections from escaping. Overall, the fully surrounded laser cutting machine ensures complete shielding, reducing the chances of accidental injuries.

II. Containment of Harmful Fumes and Dust

Laser cutting generates fumes and dust. These particles can be harmful if inhaled. Traditional laser cutting machines often release fumes into the surrounding air. Workers in the area are exposed to these harmful substances. The fully surrounded laser cutting machine addresses this problem by containing fumes and dust inside its enclosure. Additionally, most machines feature built-in filtration systems.

These filtration systems remove hazardous particles before releasing the air. As a result, air quality around the machine improves significantly. This reduces the risk of respiratory problems for operators and nearby workers. Clean air is vital for maintaining a healthy workplace, and the fully surrounded laser cutting machine ensures that.

III. Improved Operator Ergonomics

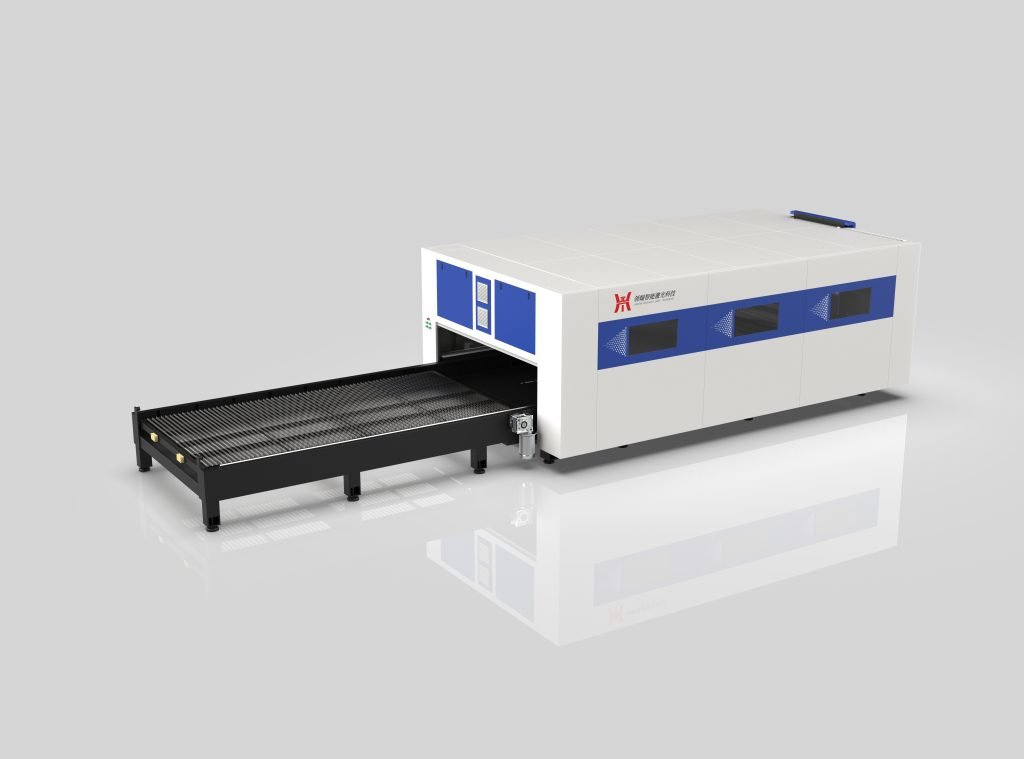

Working with a laser cutting machine often requires repetitive tasks. These tasks can lead to physical strain or injuries. The fully surrounded laser cutting machine helps improve ergonomics. Operators interact with the machine through automated controls, reducing manual labor. Most systems offer user-friendly interfaces, which simplify the operation process.

Furthermore, the enclosed design encourages safer working conditions. Operators no longer need to physically handle materials near the cutting area. This significantly reduces the risk of cuts or burns. By automating many functions, the fully surrounded laser cutting machine minimizes the risk of ergonomic-related injuries.

IV. Prevention of Accidental Contact

Accidental contact with the cutting laser can be disastrous. Traditional laser cutting machines have open designs, increasing this risk. The fully surrounded laser cutting machine eliminates accidental contact completely. Its sealed chamber prevents operators from coming into direct contact with the cutting laser.

In addition to physical barriers, these machines often include safety interlocks. These interlocks prevent the machine from operating when the enclosure is open. This ensures that no accidental exposure to the laser beam occurs. This added layer of protection makes the fully surrounded laser cutting machine much safer than traditional systems.

V. Reduction of Noise Pollution

Noise pollution is another concern in manufacturing. Laser cutting machines produce significant noise during operation. This noise can harm hearing if operators are not properly protected. A fully surrounded laser cutting machine reduces noise levels significantly. The enclosed design muffles the sound produced during cutting.

This feature benefits both operators and the surrounding work environment. Less noise means fewer distractions and a more comfortable working atmosphere. In the long run, reducing noise pollution also helps prevent hearing damage, making the workplace safer for everyone involved.

VI. Enhanced Machine Stability

The fully surrounded laser cutting machine is designed for stability. Its solid enclosure adds weight and balance. This prevents unwanted vibrations or movements during operation. Stable machines are less likely to malfunction or cause accidents. Traditional laser cutting machines may experience vibrations, affecting cutting precision and safety.

Furthermore, stable machines ensure a more consistent cutting process. This minimizes the risk of defects or errors in the final product. By ensuring stability, the fully surrounded laser cutting machine enhances both safety and productivity.

VII. Compliance with Safety Regulations

Safety regulations in manufacturing are becoming stricter. Employers must protect workers from harmful substances, noise, and radiation. The fully surrounded laser cutting machine helps companies comply with these regulations. Its enclosed design meets safety standards set by governing bodies.

By investing in a fully surrounded laser cutting machine, companies demonstrate their commitment to safety. This helps avoid potential fines or penalties for non-compliance. Furthermore, complying with regulations fosters a safer and healthier work environment.

VIII. Fire Prevention Features

Laser cutting involves high temperatures. This increases the risk of fire if not properly managed. The fully surrounded laser cutting machine includes fire prevention features. The enclosed system contains heat within the chamber, reducing fire hazards. Additionally, many machines have built-in fire suppression systems.

These systems detect any potential fire and extinguish it immediately. This proactive approach reduces the risk of serious accidents. In contrast, open laser cutting machines are more vulnerable to fire, posing a greater risk to workers and property.

IX. Conclusion

In conclusion, the fully surrounded laser cutting machine offers numerous safety benefits. Its enclosed design protects operators from laser radiation, harmful fumes, and accidental contact. Additionally, it improves air quality, reduces noise pollution, and enhances machine stability. By complying with safety regulations and incorporating fire prevention measures, these machines create a safer work environment. Companies using a fully surrounded laser cutting machine demonstrate their commitment to safety, benefiting both their workers and their productivity.