Product details

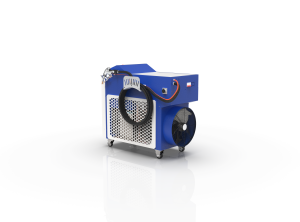

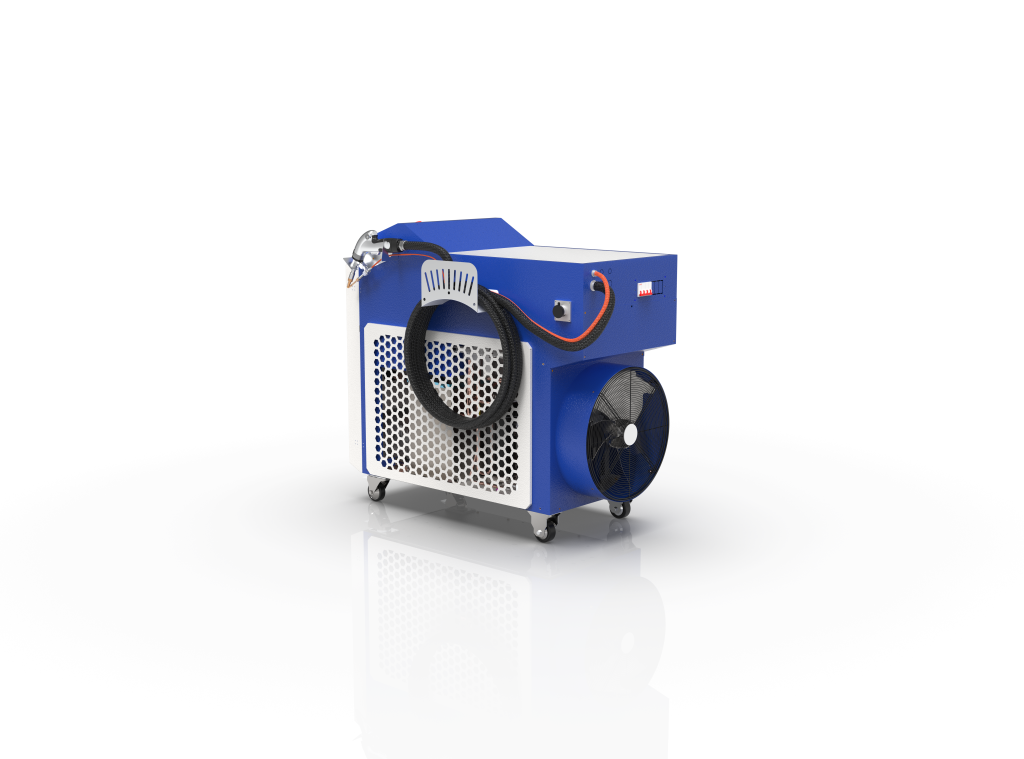

Welding cleaning machine

- Efficient Cleaning Performance:Equipped with advanced cleaning technology, this machine delivers rapid and effective cleaning. It utilizes a combination of high-pressure methods and specialized cleaning agents to remove even the toughest residues, significantly enhancing the quality of metal surfaces.

- User-Friendly Design:The welding cleaning machine features an intuitive interface that simplifies operation. Users can easily select various cleaning modes and adjust settings, making it accessible for operators of all skill levels. Its compact and lightweight design allows for easy maneuverability in tight spaces.

- Environmentally Friendly:This machine prioritizes eco-friendliness by using non-toxic cleaning agents and minimizing waste. Its design aligns with modern environmental standards, ensuring a responsible cleaning process while achieving excellent results.

All kinds of groove, one-time molding

With groove cutting module, the cutting of groove can be finished in the blanking stage, which can save the working procedure and reduce the cost

Technical specifications

| Laser power | 1000w | 1500W | 2000W | 3000W |

| Conduction Type | Fiber laser | Fiber laser | Fiber laser | Fiber laser |

| Laser Frequency | 50-5000HZ | 50-5000HZ | 1064nm | 1064nm |

| Cooling Method | Water cooling | Water cooling | Water cooling | Water cooling |

| Total Power | 5.5kw | 7.7kw | 9.5kw | 14kw |

| Fiber Cable Length | 10m | 10m | 10m | 10m |

| Eectricity Requirements | single phase 220v ±10% 50/60Hz AC | single phase 220v ±10% 50/60Hz AC | single phase 220v ±10% 50/60Hz AC | single phase 220v ±10% 50/60Hz AC |

| Welding Mode | Dot/Cricle/Line/8 mode | Dot/Cricle/Line/8 mode | Dot/Cricle/Line/8 mode | Dot/Cricle/Line/8 mode |

| Filler wire dia | 0.8-1.0-1.2-1.6mm | 0.8-1.0-1.2-1.6mm | 0.8-1.0-1.2-1.6mm | 0.8-1.0-1.2-1.6mm |

| Welding penetration | 3mm | 4mm | 5mm | 6mm |

| Working Temperature | 10 ℃-40℃ | 10 ℃-40℃ | 10 ℃-40℃ | 10 ℃-40℃ |

| Laser Frenquency | 50-5000HZ | 50-5000HZ | ||

| Laser Wavelength | 1070 +/-10 nm | 1070 +/-10 nm | ||

| Position System | Red Light Indicator | Red Light Indicator | ||

| Spot Size | 1.2-3.0mm (option) | 1.2-3.0mm (option) | ||

| Power | 220V 50&60HZ | 380V /50&60HZ | ||

| Size(L*W*H) CM | 90*40*70 | 115*65*87 | ||

| Net Weight | 160KG | 170KG | 180KG | 220KG |

| Total Power Consumption | ≤3KW | ≤4.5KW | ≤6KW | ≤9KW |

Photo Gallery

Laser scan cut, full subversion

Ordinary cutting

The energy absorption rate is low in the cutting area

Scan cut

In the cutting area, the energy absorption rate is high

Schematic diagram of laser scanning cutting principle

Double the speed

The maximum cutting speed of the same thickness plate is increased

200%

No fear of high reaction

The batch processing of high anti-reflective material can be realized without any influence of backlight

Cut costs in half

The combined cost of gas and electricity is the highest

38%

Farewell to adhesion

Adjusting the movement amplitude of the dynamic facula greatly reduces the workpiece adhesion

A positive testimonial that you think will tell people how good you are. Some positive words from an existing or a past client make a lot of difference and boost conversions on your website!

A positive testimonial that you think will tell people how good you are. Some positive words from an existing or a past client makes a lot of difference and boosts conversions on your website!