In today’s fast-evolving industrial landscape, energy efficiency has become a critical focus for manufacturers. As companies face rising energy costs and increasing environmental regulations, adopting sustainable practices is more important than ever. One of the most significant innovations driving energy savings and operational efficiency is the laser cutting machine. Particularly, the best plate laser cutting machine has revolutionized the manufacturing process by offering precision, speed, and substantial energy reductions. In this article, we will explore the role of these cutting-edge machines, their benefits, and how they are transforming the industry toward more efficient production.

I. The Growing Demand for Energy-Efficient Solutions

Industries across the globe are striving to reduce their environmental footprint while maintaining or even improving production efficiency. Traditional cutting machines, such as mechanical or plasma cutters, consume vast amounts of energy and generate significant waste. As the push for sustainability intensifies, manufacturers are turning to more innovative solutions, and laser cutting machines have emerged as a key technology in this energy-efficient shift.

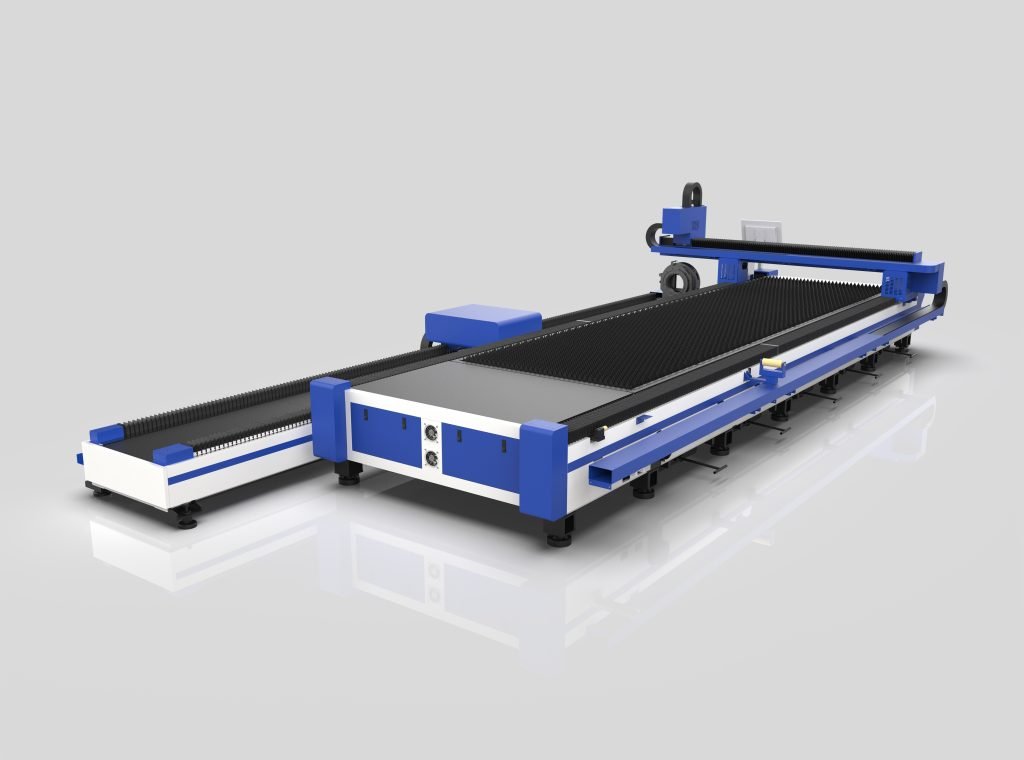

The best plate laser cutting machines are designed to operate with minimal energy consumption, making them a smart investment for manufacturers looking to cut costs while meeting sustainability goals. Through technological advancements, these machines now offer greater precision, increased speed, and lower energy usage, which are critical in today’s competitive marketplace.

II. Understanding How Laser Cutting Machines Save Energy

Laser cutting machines work by using a concentrated laser beam to cut through materials like metal with extreme precision. Unlike traditional cutting methods that require physical contact or heat-based techniques, laser cutting machines vaporize material along the cut path, resulting in a cleaner, more efficient process. This method not only reduces material waste but also requires far less energy.

1. Key Mechanisms of Energy Efficiency

a. Reduced Heat Generation

One of the most energy-efficient aspects of laser cutting is its ability to generate minimal heat during the cutting process. Traditional methods such as plasma cutting generate excessive heat, which requires energy-intensive cooling systems to manage. In contrast, laser cutting machines focus their energy precisely on the cutting area, minimizing heat dispersion and the subsequent need for cooling.

b. Minimal Material Waste

Another reason why the best plate laser cutting machines excel in energy savings is their ability to produce accurate cuts with minimal waste. The precision of laser technology ensures that every cut is exact, maximizing the use of raw materials. By reducing the amount of scrap material generated, manufacturers not only save on materials but also on the energy that would otherwise be required to process excess waste.

c. Optimized Power Usage

The best plate laser cutting machines come equipped with intelligent software that optimizes the cutting path and adjusts the laser’s power output to suit the material and thickness being cut. This means that energy is only used when and where it’s needed, reducing overall power consumption.

III. The Impact of Fiber Laser Technology

Fiber lasers represent one of the most significant advancements in laser cutting technology, particularly when it comes to energy efficiency. Compared to traditional CO2 lasers, fiber lasers offer a more focused beam, faster cutting speeds, and lower energy consumption.

1. Advantages of Fiber Lasers Over CO2 Lasers

a. Higher Efficiency

Fiber lasers are inherently more energy-efficient than CO2 lasers. The energy required to generate a laser beam in a fiber laser is lower, and the beam is more focused, which translates into faster cutting times and reduced energy usage.

b. Low Maintenance

Unlike CO2 lasers, which require frequent maintenance due to their gas-based nature, fiber lasers are solid-state machines. This reduces downtime for repairs and maintenance, resulting in continuous operation and lower overall energy use.

c. Faster Cutting Speeds

Fiber lasers can cut through a variety of materials, including thick metals, at much faster speeds compared to CO2 lasers. This speed increase not only boosts productivity but also reduces the time the machine is in operation, contributing to energy savings.

d. Longer Lifespan

The best plate laser cutting machines utilizing fiber laser technology have longer lifespans and are more durable, making them a more sustainable and energy-efficient investment for manufacturers.

IV. How the Best Plate Laser Cutting Machine Enhances Production Efficiency

Manufacturers worldwide are recognizing the benefits of investing in the best plate laser cutting machine. These machines not only drive energy savings but also enhance overall production efficiency. The key lies in their automation capabilities, precision, and adaptability to various materials and production needs.

1. Automation and Intelligent Software

Many of the best plate laser cutting machines come with automated features that optimize every aspect of the cutting process. Intelligent software systems guide the machine’s operations, from determining the most efficient cutting path to adjusting power settings based on material thickness. This high level of automation reduces human error, decreases waste, and optimizes energy use, making production lines more efficient.

Moreover, these automated systems allow manufacturers to run their machines continuously with minimal supervision. By reducing downtime between operations, manufacturers can maintain consistent production rates while minimizing energy consumption.

2. Versatility and Adaptability

Another significant advantage of laser cutting machines is their ability to cut through a wide variety of materials, from steel and aluminum to more complex alloys. The best plate laser cutting machines are incredibly versatile, which allows manufacturers to switch between projects without needing to retool or change machines. This adaptability increases operational efficiency and reduces the need for multiple types of cutting equipment, which would otherwise consume more energy and space.

Additionally, laser cutting machines can handle a wide range of thicknesses with ease. Their adaptability to different material types and thicknesses means that manufacturers can complete more diverse projects without requiring multiple machines or significant downtime, thus improving energy efficiency.

3. Lower Maintenance and Operating Costs

The best plate laser cutting machines are designed with longevity and durability in mind. Their solid-state components and reduced reliance on consumables mean that they require less maintenance and fewer part replacements compared to traditional cutting machines. With less downtime for repairs and fewer parts to replace, these machines reduce both operational and energy costs over time.

Furthermore, the lower maintenance requirements of fiber laser machines translate into long-term savings for manufacturers. Since the machine’s laser does not come into physical contact with the material, wear and tear are minimized, and the machine remains in optimal working condition for longer.

V. The Importance of Partnering with the Right Supplier

While laser cutting machines offer significant benefits, choosing the right supplier is crucial to ensuring that manufacturers get the most out of their investment. The best plate laser cutting machine suppliers provide not only high-quality machines but also ongoing support, training, and maintenance services. By partnering with a reliable supplier, manufacturers can maximize the lifespan and efficiency of their equipment.

1. Key Considerations When Choosing a Supplier

a. Quality of Machines

It’s essential to work with suppliers who offer durable, energy-efficient laser cutting machines equipped with the latest technology, such as fiber lasers.

b. After-Sales Support

The best suppliers provide comprehensive support, including installation, training, and maintenance, ensuring that manufacturers can optimize their production processes.

c. Customization Options

Many suppliers offer customized solutions tailored to specific production needs, ensuring that manufacturers can get machines that perfectly fit their operational requirements.

VI. Conclusion

In conclusion, laser cutting machines are transforming the manufacturing industry by delivering substantial energy savings and enhancing production efficiency. The best plate laser cutting machines, particularly those equipped with fiber laser technology, offer faster cutting speeds, greater precision, and lower energy consumption, making them a smart investment for manufacturers looking to improve sustainability and reduce operational costs.

By partnering with reputable suppliers, manufacturers can unlock the full potential of these machines, ensuring that their production processes are optimized for both efficiency and energy savings. As energy costs rise and sustainability becomes a top priority, the role of energy-efficient laser cutting machines in revolutionizing the industry will only continue to grow.