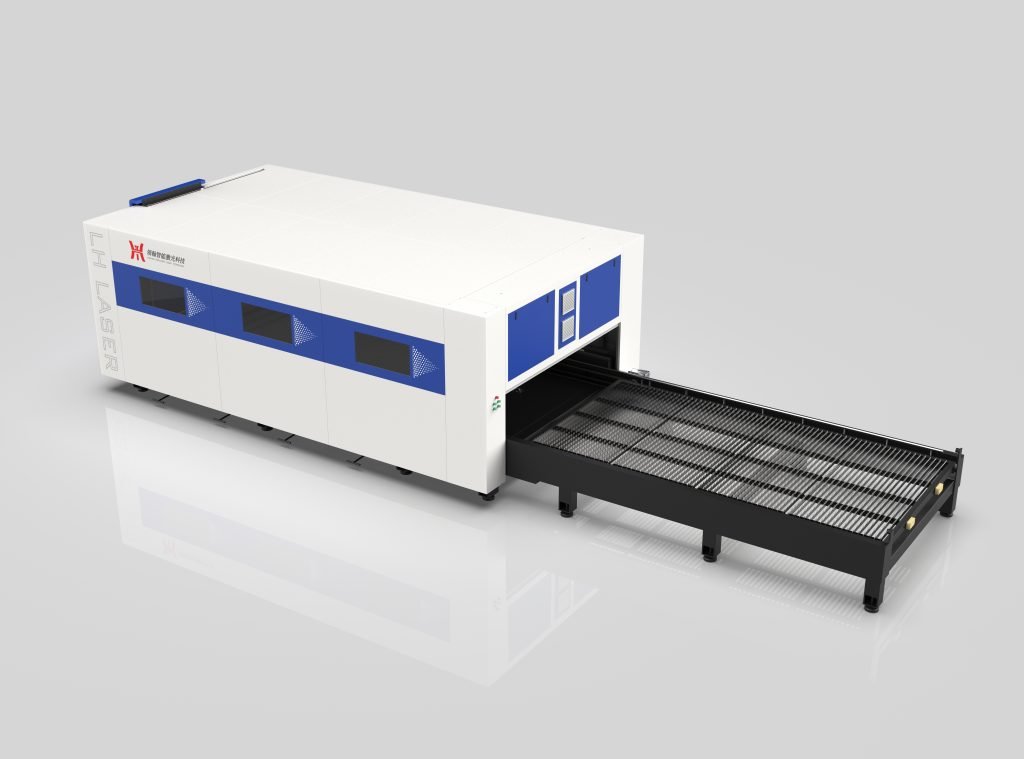

In modern manufacturing, efficiency is key to success. Companies must optimize production processes to remain competitive. A plně obklopený laserový řezací stroj offers numerous advantages in this regard. These machines enhance productivity, precision, and safety. This article explains how you can maximize output using a fully surrounded laser cutting machine, including those specifically designed as a cortadora laser para metal.

I. Enhanced Speed and Efficiency

A fully surrounded laser cutting machine operates at higher speeds than traditional systems. The enclosed design ensures a controlled environment. This reduces external disruptions, allowing the machine to work more efficiently. Faster cutting speeds mean higher production rates, which leads to maximizing output.

Additionally, the machine can handle continuous cutting without frequent stops. This uninterrupted operation is vital in boosting production. For cutting metal, using a cortadora laser para metal with a fully enclosed system increases output dramatically.

II. Improved Cutting Precision

Precision is essential in any cutting job. A fully surrounded laser cutting machine delivers exceptional accuracy. The enclosed chamber stabilizes the machine, reducing vibrations that can affect cut quality. This level of precision leads to fewer errors and less waste.

Moreover, the machine’s laser can cut intricate designs with minimal effort. This precision ensures that each piece meets exact specifications. When working with metals, a cortadora laser para metal provides the precise cuts needed for high-quality output.

III. Reduction in Setup Time

Another advantage of a fully surrounded laser cutting machine is its reduced setup time. The machine’s automated features streamline the preparation process. This allows operators to set up jobs faster, leading to more time for actual cutting.

With traditional cutting systems, setup can be time-consuming. The automation in a fully surrounded laser cutting machine minimizes this, further increasing efficiency. For metal cutting, a cortadora laser para metal ensures quicker transitions between jobs, resulting in higher productivity.

IV. Consistency in Production

Consistency is critical for high-output manufacturing. A fully surrounded laser cutting machine offers consistent results, even over long production runs. The enclosed environment maintains stability, ensuring that cuts remain uniform from start to finish.

In contrast, open machines may experience fluctuations due to environmental factors. With a fully enclosed system, you can expect reliable performance throughout the day. When cutting metal, using a cortadora laser para metal guarantees consistent quality across multiple pieces, further boosting output.

V. Improved Material Handling

Efficient material handling is crucial for maximizing output. A fully surrounded laser cutting machine often comes with automated material handling features. These systems load and unload materials automatically, reducing manual labor.

This automation speeds up production, as operators spend less time handling materials. For metal cutting jobs, a cortadora laser para metal equipped with automated material handling can cut multiple sheets of metal with minimal intervention.

VI. Lower Maintenance Downtime

Maintenance can significantly reduce output if machines need frequent repairs. A fully surrounded laser cutting machine minimizes downtime due to its durable and enclosed design. The enclosed system prevents debris from entering critical components, reducing wear and tear.

Fewer breakdowns mean more cutting time, which translates to higher output. Regular maintenance is still required, but the fully surrounded laser cutting machine experiences fewer unexpected failures. In metal cutting, a cortadora laser para metal benefits greatly from this reduced maintenance downtime, keeping production on track.

VII. Efficient Energy Use

Energy efficiency is another factor in maximizing output. A fully surrounded laser cutting machine uses energy more effectively. The enclosed chamber contains the laser’s power, reducing energy loss. This concentrated energy results in faster, more efficient cutting.

Additionally, many machines are designed to optimize power usage based on the material being cut. For instance, a cortadora laser para metal adjusts its laser intensity depending on the thickness of the metal. This precision energy management ensures maximum output without wasting resources.

VIII. Safer Work Environment

A safe work environment boosts productivity. The fully surrounded laser cutting machine creates a safer workspace by enclosing the laser beam. This reduces the risk of accidents or injuries, allowing operators to work confidently and efficiently.

Furthermore, the enclosed design prevents harmful fumes or debris from escaping into the work area. Cleaner air and less exposure to hazardous materials contribute to a more productive workforce. A cortadora laser para metal ensures that metal dust and particles are contained, protecting workers and maximizing output.

IX. Faster Transition Between Materials

Switching between different materials can slow down production. However, a fully surrounded laser cutting machine simplifies this process. The machine’s automated systems adjust cutting parameters based on the material.

For example, switching from plastic to metal is seamless with a cortadora laser para metal. The machine automatically adjusts laser power and cutting speed, minimizing downtime. This flexibility allows manufacturers to handle a wide variety of jobs without sacrificing productivity.

X. Cost-Effective Production

Cost efficiency plays a key role in maximizing output. A fully surrounded laser cutting machine reduces costs through several means. First, its precision reduces material waste. Fewer errors mean less material is discarded, which lowers costs.

Second, the machine’s efficiency reduces energy consumption. Lower energy costs contribute to overall savings. Finally, the machine’s durability and low maintenance needs reduce the cost of repairs and downtime. Using a cortadora laser para metal offers all these benefits, making metal cutting both cost-effective and high-yield.

XI. Maximizing Long-Term Output

In the long term, a fully surrounded laser cutting machine offers sustained high output. Its reliability and efficiency ensure continuous production without frequent interruptions. The enclosed system’s advanced features support high-volume operations.

For businesses focused on metal cutting, a cortadora laser para metal guarantees long-term efficiency and precision. The investment in a fully enclosed machine pays off through consistent high output and reduced operational costs.

XII. Závěr

In conclusion, a fully surrounded laser cutting machine is essential for maximizing output. Its advanced design improves speed, precision, and safety. Automated features and reduced maintenance needs further enhance efficiency. When cutting metal, a cortadora laser para metal delivers superior performance, ensuring consistent and high-quality output.

By choosing a fully enclosed system, manufacturers can significantly increase production rates while maintaining product quality. This combination of speed, precision, and efficiency makes the fully surrounded laser cutting machine an invaluable tool for maximizing output in modern manufacturing.