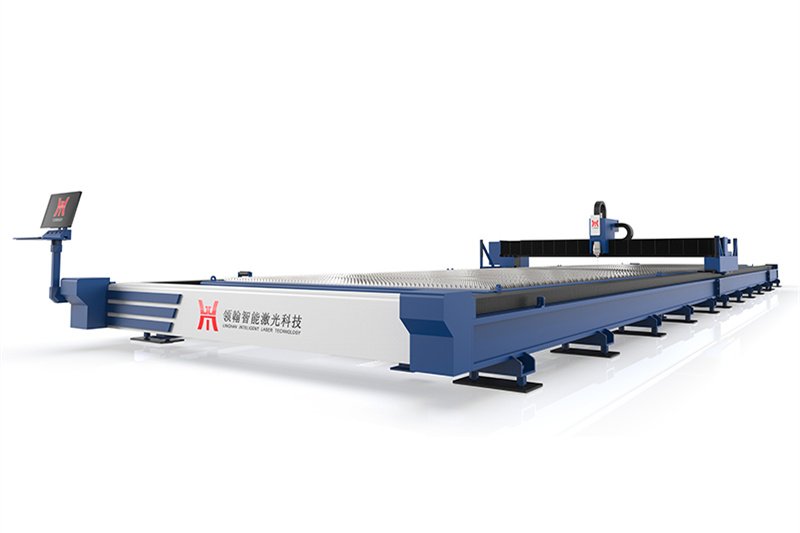

With advancements in technology, laser cutting has become an essential part of modern manufacturing, especially in plate processing. A Čína laserový řezací stroj na desky offers high precision and efficiency, making it widely used across industries. As a China laser plate cutting machine supplier, we aim to help you understand how these machines work and why they provide a superior cutting experience for your business needs.

What is a Laser Plate Cutting Machine?

A laserový řezací stroj na desky uses a high-energy laser beam to cut materials like metal, plastic, and wood. This beam is focused onto a tiny spot on the material’s surface, generating high temperatures that melt or vaporize the material, achieving a precise cut. Compared to traditional methods, laser cutting has smoother cuts, high accuracy, and faster speeds, making it ideal for precise and complex cutting needs.

Laser plate cutting machines can cut non-contact, don’t require tool changes, and allow automated control, perfect for high-volume production. For industries needing accuracy and efficiency, a laser plate cutting machine is an indispensable tool.

Key Components of a Laser Plate Cutting Machine

To understand how a China laser plate cutting machine works, let’s look at its primary components:

1. Laserový zdroj

The laser source is the heart of the cutting machine, generating the high-energy laser beam. Different laser types, such as CO2 lasers, fiber lasers, and YAG lasers, cater to various materials and cutting requirements. China laser plate cutting machine suppliers typically recommend a suitable laser source based on the specific needs of their customers to ensure optimal cutting results.

CO2 Laser: Ideal for cutting non-metal materials like wood, acrylic, and plastic.

Fiber Laser: Known for high efficiency and stability, fiber lasers are widely used for metal cutting.

YAG Laser: Suitable for precision machining but more energy-intensive, mainly used for fine cutting.

2. Transmission System

After emission, the laser beam travels through a transmission system using fiber optics or mirrors, delivering it to the cutting head. Fiber transmission is commonly used in modern laser cutting as it reduces laser loss and ensures stable, efficient cutting.

3. Focusing Lens

During cutting, the laser beam needs to be focused onto the material’s surface through a focusing lens. This lens condenses the beam to an ultra-small point with high heat, reaching temperatures over 1,000°C. This high energy density allows the laser to melt or vaporize the material efficiently.

4. Control System

A sophisticated control system governs the laser movement path, cutting speed, and power. Modern systems accept CAD files and convert them into cutting paths, enabling fully automated control and ensuring cutting precision.

5. Asistenční plyn

Assist gases (such as oxygen, nitrogen, and air) play a vital role in laser cutting. Depending on the material and cut requirements, assist gases are used at different pressures. They help blow away molten material, cool the cut zone, and prevent burn marks.

How a Laser Plate Cutting Machine Works

Now that we know the components, let’s dive into the working principles of a China laser plate cutting machine. The entire cutting process involves the following steps:

1. Laser Emission and Focusing

The laser source generates a laser beam, which travels through fiber or mirrors to the focusing lens. This lens focuses the beam to a tiny spot on the material’s surface, forming a high-temperature area. The laser spot temperature can reach over 3,000°C, which is hot enough to melt or vaporize even hard materials like metal.

2. Heating, Melting, or Vaporizing Material

When the laser spot contacts the material, it heats it rapidly. Different cutting modes achieve various effects:

Melt Cutting: The laser heats the material until it melts, and then assist gas blows the molten material out of the cut line. Melt cutting is commonly used for metals.

Vaporization Cutting: The laser heats the material to the point where it vaporizes, making it suitable for thin metals and plastics requiring precise cuts.

3. Assist Gas Blows Away Molten Material

During cutting, assist gas is injected into the cutting area to remove molten material and oxidation from the cut edge. Different gases suit different materials:

Oxygen: Used for metals, increasing cutting speed but causing oxidation.

Nitrogen: Used for stainless steel and aluminum, resulting in smooth, oxidation-free edges.

Air: A low-cost option for general plate cutting; it’s efficient but may result in lower cut quality.

4. CNC System Controls Cutting Path

The CNC system follows pre-set CAD files to control the cutting path, speed, and laser power. Precision CNC operations ensure consistent, accurate cuts, making laser cutting ideal for complex designs and detailed work.

How to Choose a Laser Plate Cutting Machine?

When choosing a China laser plate cutting machine, it’s essential to know the specific features and requirements that fit your business. Here are some tips:

1. Choose Based on Material Requirements

Different machines specialize in various materials. If your work involves metal cutting, fiber laser machines are often best. If you also work with non-metal materials, consider CO2 lasers.

2. Consider the Power and Cutting Speed

Power and speed are crucial factors. Higher-powered lasers can cut thicker materials faster, which is important for high-volume operations. However, power also impacts laser plate cutting machine price, so select a machine that balances power with budget needs.

3. Look for Safety Features

Safety features such as automatic shut-off and protective housing are essential, especially for high-powered machines used in industrial settings. Reliable laser plate cutting machine suppliers offer options with advanced safety features for safer operations.

4. Select a Reputable Supplier with Support

Choosing a reputable China laser plate cutting machine supplier ensures quality control and reliable after-sales support. Suppliers that offer warranties and customer support add value, helping you maximize your investment.

Závěr

A China laser plate cutting machine offers unmatched precision, efficiency, and flexibility, making it a valuable asset in modern manufacturing. From metal processing and automotive production to signage and electronics, laser cutting delivers superior quality and cost efficiency. By understanding how these machines work, you can make informed choices that suit your production needs.

When considering a purchase, look at the laser plate cutting machine price and compare models to find one that meets your budget and performance requirements. Selecting the right machine can transform your production capabilities, improve quality, and increase output. We hope this guide has provided you with valuable insights into how laser plate cutting machines work and how they can benefit your business.