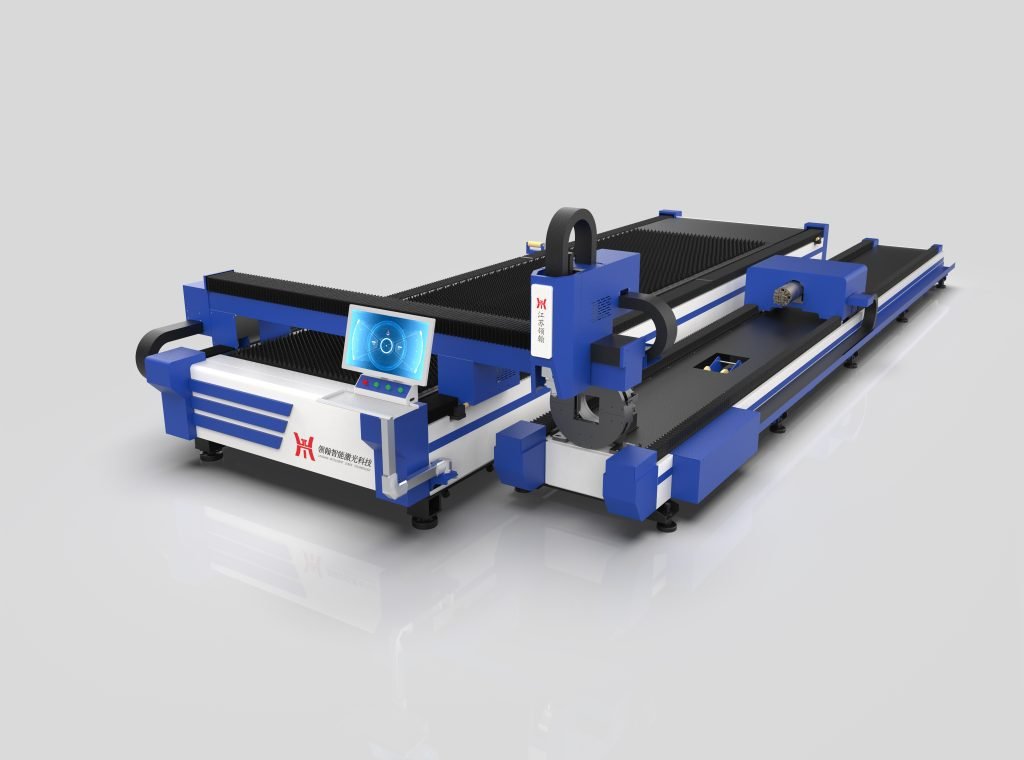

Laser cutting technology has revolutionized modern manufacturing. It allows precise cutting of various materials with ease. Among the most versatile tools is the china plate tube laser cutting machine. This machine is capable of cutting both flat plates and tubes. With its flexibility, businesses can cut multiple materials quickly and efficiently. In this article, we’ll explore how to use a laser plate cutting machine for multi-material cutting, highlighting its advantages and applications.

أنا. Understanding the Laser Plate Cutting Machine

A laser plate cutting machine uses a high-powered laser beam to cut through materials. The laser beam vaporizes the material, resulting in a clean cut. Manufacturers can use this technology to cut a wide range of materials. These include metals, plastics, and even some composites. The آلة قطع أنبوب اللوحة الصينية بالليزر adds extra versatility by cutting both flat sheets and tubular structures. This makes it ideal for industries that require precision in various material types.

ثانيا. Versatility in Material Cutting

One of the greatest advantages of a china plate tube laser cutting machine is its ability to cut multiple materials. These machines are not limited to one type of material. They can process metals such as steel, aluminum, and copper. This flexibility allows manufacturers to handle different projects without switching machines. The laser plate cutting machine also excels at cutting plastics and composite materials, offering precision across different textures.

ثالثا. Cutting Metals with Laser Technology

Metal cutting is the primary application for the china plate tube laser cutting machine. Steel, aluminum, and copper are common materials cut with this technology. The machine’s laser beam focuses intensely on the metal, ensuring a smooth cut. It can handle thick plates as well as thin tubes. This ability allows manufacturers to work with different metal gauges in one setup.

For cutting metal plates, the laser plate cutting machine adjusts the laser’s intensity based on material thickness. This results in clean, sharp edges without requiring further processing. This precision makes it ideal for industries such as automotive and aerospace, where high tolerances are essential.

رابعا. Cutting Plastics and Composites

The china plate tube laser cutting machine isn’t just limited to metals. It can also cut plastics and composites with equal precision. Plastics like acrylic and polycarbonate are commonly cut using laser technology. The laser plate cutting machine makes smooth, burr-free cuts on these materials. This ability expands its usability in industries such as packaging and electronics.

Composites, like fiberglass or carbon fiber, are more challenging to cut. However, with the right settings, a china plate tube laser cutting machine can achieve excellent results. The machine’s flexibility makes it easier to switch between cutting metals and non-metals, streamlining production.

الخامس. Cutting Tubes with Precision

The china plate tube laser cutting machine offers a unique advantage: tube cutting. Tubular materials, such as pipes or structural supports, are common in construction and manufacturing. The laser cutting machine can cut round, square, and rectangular tubes with precision. This feature eliminates the need for separate machines to handle different shapes. The laser’s ability to adjust to different material sizes and shapes makes it a highly adaptable tool.

For manufacturers dealing with both plates and tubes, this machine saves time and space. Instead of investing in two separate machines, businesses can rely on one china plate tube laser cutting machine to handle multiple tasks.

السادس. The Role of Automation in Multi-Material Cutting

Automation plays a key role in the efficiency of a laser plate cutting machine. Modern machines use intelligent software to control the laser’s settings. This software adjusts the cutting parameters based on the material type and thickness. It ensures that the machine delivers the best possible results for each material.

With automation, the china plate tube laser cutting machine can switch seamlessly between materials. Operators can pre-program the machine to handle various tasks in sequence. This reduces downtime and increases productivity. It also minimizes human error, resulting in higher precision.

7- السابع Overcoming Challenges in Multi-Material Cutting

Cutting different materials requires careful consideration. Each material reacts differently to laser cutting. Metals require a high-power laser, while plastics may need lower power. The laser plate cutting machine addresses these challenges through its adjustable settings. Operators can fine-tune the laser’s intensity to suit the material. This versatility allows manufacturers to achieve clean cuts across different materials.

For example, cutting aluminum may require a different gas than cutting steel. The china plate tube laser cutting machine can automatically switch between gases, ensuring the best results for each material. This adaptability reduces the need for manual adjustments, making the process smoother and more efficient.

ثامناً. Benefits of Multi-Material Cutting with a Laser Machine

Using a china plate tube laser cutting machine for multi-material cutting offers several benefits. First, it reduces the need for multiple machines, saving both space and investment costs. Second, it improves efficiency by allowing businesses to cut different materials in one production run. Third, it increases precision across materials, ensuring high-quality results every time.

The laser plate cutting machine also reduces the need for post-processing. Unlike traditional cutting methods, laser cutting leaves smooth, burr-free edges. This reduces the time spent on finishing tasks like sanding or polishing. It also enhances the overall quality of the final product, making it more appealing to customers.

IX. Applications of Multi-Material Cutting

The versatility of the china plate tube laser cutting machine makes it suitable for a wide range of industries. In construction, it can cut structural steel beams and pipes with ease. In the automotive sector, it can cut metal plates for car bodies and tubular components for exhaust systems.

Manufacturers in the aerospace industry also benefit from the laser plate cutting machine. Its ability to cut high-strength metals and lightweight composites ensures that aircraft parts meet strict safety standards. The machine’s adaptability allows aerospace companies to switch between different materials seamlessly, improving production efficiency.

إكس. خاتمة

The china plate tube laser cutting machine is a game-changer in the world of multi-material cutting. Its ability to handle both plates and tubes makes it an incredibly versatile tool. From metals to plastics and composites, this machine can tackle various materials with precision and ease. Automation and advanced software further enhance its capabilities, allowing businesses to switch between materials without losing efficiency.

By using a laser plate cutting machine, manufacturers can streamline their production processes, improve product quality, and reduce costs. Its adaptability and precision make it a valuable asset in industries ranging from construction to aerospace. As laser cutting technology continues to evolve, we can expect even more innovations that push the boundaries of what’s possible in multi-material cutting.