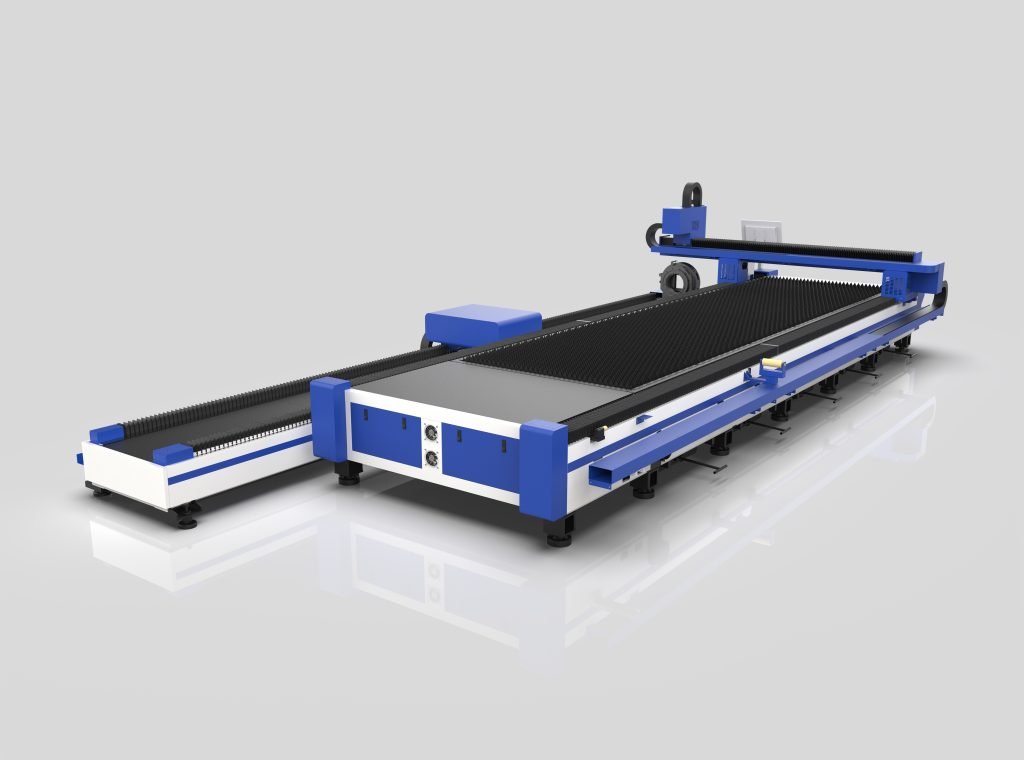

In modern manufacturing, efficiency and adaptability are key. The آلة قطع الصفائح has evolved to meet these demands. One of the most significant advancements in this field is modular design. By enabling rapid reconfiguration, modularity transforms how manufacturers use plate cutting machines. This article explores the benefits of modular design in plate cutting machines, with a focus on its impact on the industry and the growing use of laser plate cutting machines.

أنا. Understanding Modular Design in Plate Cutting Machines

Modular design refers to creating machines with interchangeable parts or modules. This approach allows for quick adjustments and upgrades. In the context of a plate cutting machine, modularity means operators can change components without replacing the entire machine. This flexibility is crucial in today’s fast-paced manufacturing environment.

ثانيا. The Benefits of Modular Design

First, modular design offers significant cost savings. Instead of purchasing a new plate cutting machine when requirements change, businesses can simply swap out specific modules. This approach reduces both initial investment and long-term expenses. Moreover, modularity extends the lifespan of the plate cutting machine, as outdated components can be replaced with newer, more efficient ones.

Second, modular design enhances customization. Every manufacturing process is unique, and plate cutting machines must adapt accordingly. By using modular components, companies can tailor their machines to specific needs. This customization ensures optimal performance, whether in general metalworking or specialized industries like aerospace.

Third, modular design supports rapid technological advancements. As technology evolves, manufacturers need to stay competitive. With a modular plate cutting machine, integrating new technology becomes straightforward. For instance, businesses can easily upgrade from traditional cutting methods to a laser plate cutting machine. This seamless transition allows companies to adopt cutting-edge technology without significant downtime or investment.

ثالثا. Rapid Reconfiguration for Efficiency

In addition to modularity, rapid reconfiguration is a vital feature. Rapid reconfiguration allows manufacturers to quickly adapt their plate cutting machines to different tasks. This flexibility is particularly beneficial in industries that require frequent changes in production lines. By reducing setup time, companies can increase productivity and reduce costs.

Moreover, rapid reconfiguration aligns with the trend towards smaller production runs. As consumer demand becomes more personalized, manufacturers must produce smaller batches of products. A plate cutting machine with rapid reconfiguration capabilities can quickly switch between tasks, making it ideal for just-in-time manufacturing.

رابعا. Case Study: Modular Design in Laser Plate Cutting Machines

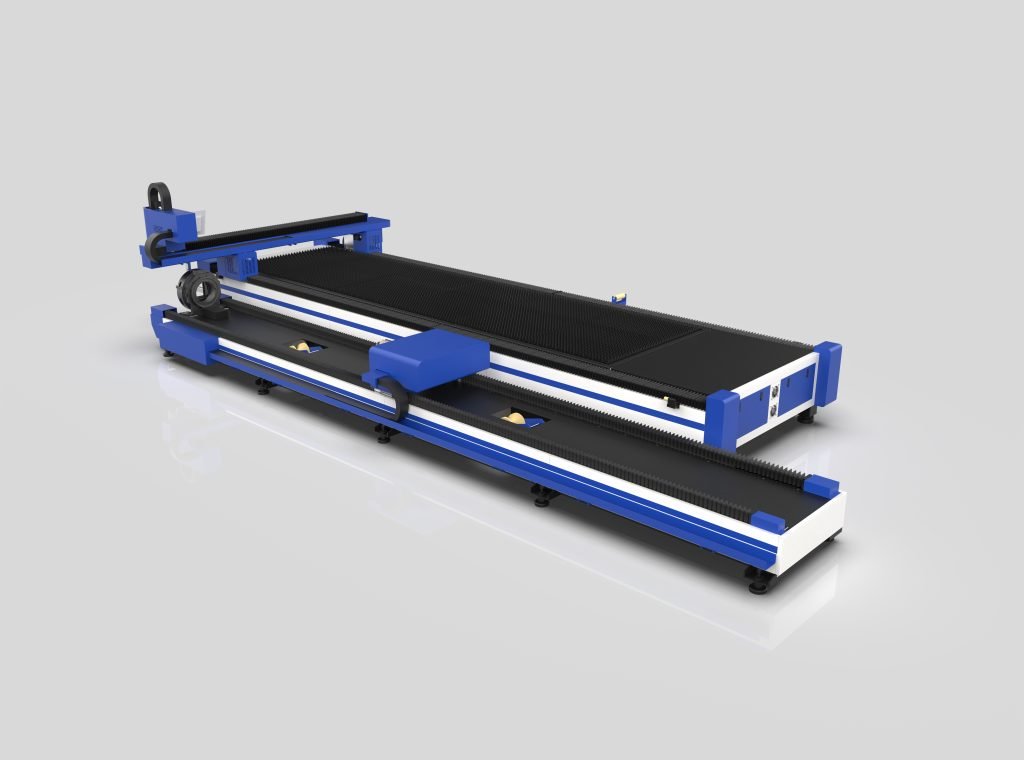

Let’s consider a practical example. A company specializing in custom metalwork needed a flexible plate cutting machine. They chose a laser plate cutting machine with modular design features. Initially, the company used the machine for standard steel cutting. However, as their product line expanded, they needed to cut a wider variety of materials, including aluminum and titanium.

Instead of purchasing multiple machines, the company upgraded their existing laser plate cutting machine. They added new modules specifically designed for cutting different materials. This upgrade took only a few hours, and production continued with minimal interruption. The modular design saved the company significant costs and allowed them to meet new customer demands efficiently.

Furthermore, the rapid reconfiguration capabilities of their laser plate cutting machine enabled the company to switch between materials quickly. They could fulfill smaller, customized orders without sacrificing efficiency. This adaptability gave them a competitive edge in a market increasingly driven by customization.

الخامس. The Role of Laser Technology

Laser technology plays a crucial role in the evolution of plate cutting machines. A laser plate cutting machine offers precision and speed unmatched by traditional methods. When combined with modular design, laser cutting technology becomes even more powerful. Modular components can enhance the laser’s capabilities, such as adding features for cutting different materials or increasing cutting speed.

Additionally, laser technology is inherently flexible. A laser plate cutting machine can easily adjust to various thicknesses and materials, making it ideal for a modular setup. By incorporating laser technology into a modular design, manufacturers can achieve greater versatility and efficiency.

السادس. Challenges and Considerations

While modular design and rapid reconfiguration offer many benefits, they also present challenges. One challenge is ensuring compatibility between modules. Manufacturers must carefully design modules to fit seamlessly together. This requires precise engineering and standardization across components.

Another consideration is the initial investment. Although modular design can save money in the long run, the upfront cost may be higher. Companies must weigh these costs against the potential benefits of flexibility and longevity. However, as modular technology becomes more widespread, these costs are likely to decrease.

Moreover, training is essential. Operators need to understand how to reconfigure the plate cutting machine quickly and safely. Training programs should emphasize the importance of proper setup and maintenance to ensure smooth operation.

7- السابع Future Prospects

The future of plate cutting machines lies in further integration of modular design and advanced technologies like laser cutting. As demand for customization and efficiency grows, more manufacturers will adopt these innovations. The widespread use of laser plate cutting machines with modular capabilities is likely to increase. This trend will drive competition, leading to more affordable and accessible modular solutions.

Furthermore, we can expect to see advancements in automation within modular systems. Automated modules could reconfigure themselves based on real-time data, further reducing downtime and increasing efficiency. This level of automation would revolutionize how plate cutting machines operate, making them even more adaptable to changing market demands.

ثامناً. خاتمة

In conclusion, modular design and rapid reconfiguration are transforming the plate cutting machine industry. These innovations provide significant benefits, including cost savings, customization, and adaptability. The integration of laser technology further enhances these advantages, making the laser plate cutting machine a powerful tool in modern manufacturing. Despite some challenges, the future of modular plate cutting machines looks promising, with continued advancements likely to drive further improvements. As the industry evolves, manufacturers who embrace these technologies will be well-positioned to succeed in an increasingly competitive market.