Product details

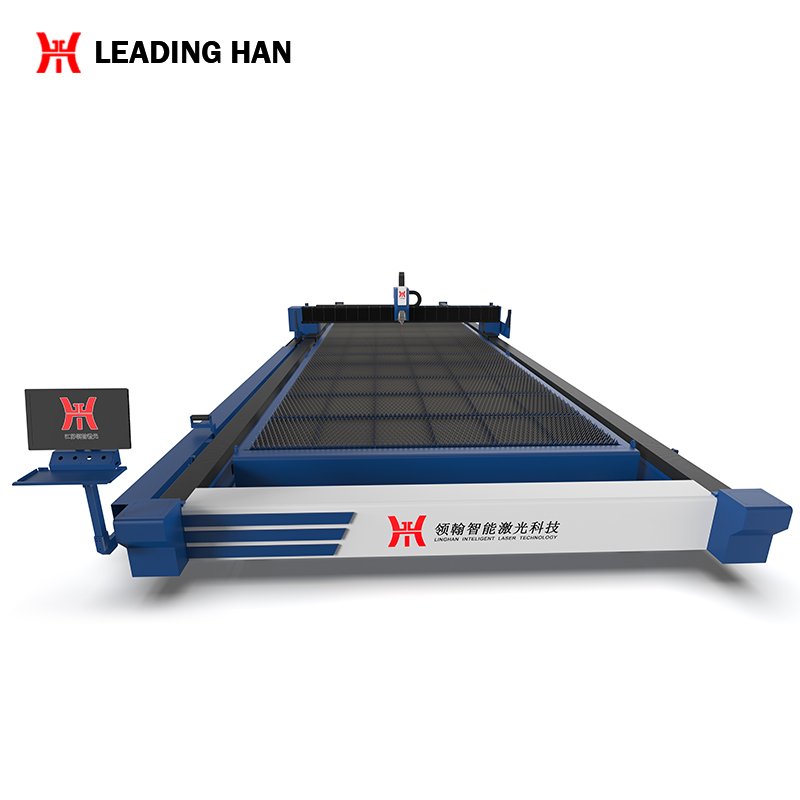

GF14032 Ground Rail Laser Cutting Machine

- The high-precision guide rail system ensures stability and efficient operation during the cutting process, suitable for long-term continuous work.

- With high-precision laser cutting capabilities, it can handle complex graphics and materials of various thicknesses, ensuring smooth and neat cutting edges.

- It supports the cutting of a variety of materials, such as stainless steel, carbon steel, aluminum, etc., and is widely used in multiple industries to meet the needs of different customers.

- Modular design and high-quality components make equipment maintenance simple, reduce operating costs, and increase the service life of the equipment.

- Equipped with multiple safety protection systems to ensure the safety of operators and effectively reduce the failure rate of equipment.

All kinds of groove, one-time molding

With groove cutting module, the cutting of groove can be finished in the blanking stage, which can save the working procedure and reduce the cost

Technical specifications

GF14032 Ground Rail Laser Cutting Machine

| Country of origin | China |

| Brand name | Leading han |

| Product name | Fiber laser cutting machine |

| Power | 1,500 W 2000W 3000W6000W12000W (optional) |

| Plate processing size | customizable |

| The X / Y-axis positioning accuracy | ±0.05 mm |

| X, Y-axis uniaxial maximum positioning speed | 120 m/min |

| X, Y-axis maximum linkage speed | 140 m/min |

| Repeat positioning accuracy | ±0.03 mm/m |

| Maximum running speed | 80 Meters / minute |

| Z-axis travel | 300mm |

| Positioning accuracy | ±0.03mm |

| Lubrication type | YYC |

| Max accelerated speed | 1.2G |

| Applicable Material | Stainless Steel Carbon Steel Aluminum etc. |

| Laser source brand | RAYCUS\IPG |

| Laser head brand | Raytools\Boci |

| Servo motor brand | DELTA |

| Guiderail | On the silver |

| Control system brand | Cypcut |

| Weight | 2000-10000KG |

| Provide after-sales service | Online support |

Photo Gallery

Laser scan cut, full subversion

Ordinary cutting

The energy absorption rate is low in the cutting area

Scan cut

In the cutting area, the energy absorption rate is high

Schematic diagram of laser scanning cutting principle

Double the speed

The maximum cutting speed of the same thickness plate is increased

200%

No fear of high reaction

The batch processing of high anti-reflective material can be realized without any influence of backlight

Cut costs in half

The combined cost of gas and electricity is the highest

38%

Farewell to adhesion

Adjusting the movement amplitude of the dynamic facula greatly reduces the workpiece adhesion

A positive testimonial that you think will tell people how good you are. Some positive words from an existing or a past client make a lot of difference and boost conversions on your website!

A positive testimonial that you think will tell people how good you are. Some positive words from an existing or a past client makes a lot of difference and boosts conversions on your website!